BPA Free

Elastic Resin(#3130)

- High soft and high elastic

- TPU-like material

- Good tear resistance

- Flexibility

C6H6 Free

What is elasticity of material?

Elasticity is theability of a deformed material body to return to its original shape and size when the forces causing the deformation are removed.

Properties of Elastic Resin(3130)

It is an excellent engineering-grade material for 3D Printing flexible parts.

Highly elastic and soft

Elongation at Failure: 80%-105%. 3D printed functional parts using 3130 resin are very elastic and can be freely stretched and bent without breaking. when you stop, it goes back to its original shape.

TPU-like material

Good simulation of 50~60A TPU(Thermoplastic Polyurethane ). Complex mesh structure can be printed.

Excellent tear resistance

Not easy to crack. High tear resistance indicates that the object is resistant to abrasion.

Flexibility

The surface hardness is 60A (Shore A hardness), meaning a certain softness and a certain hardness. Small tires can be printed.

Specifications of Elastic Resin(3130)

Content Data value Post-Cured Testing method Ultimate Tensile Strength 1.21MPa 2.86MPa ASTM D 412-06 (A) Stress at 50% elongation 0.62MPa 0.64MPa ASTM D 412-06 (A) Stress at 100% elongation 1.18Mpa 1.20MPa ASTM D 412-06 (A) Elongation at Failure 80% 105% ASTM D 412-06 (A) Tear strength 6.7kN/m 16.1kN/m ASTM D 624-00 Shore hardness 60A 70A ASTM D2240 You can download the parameter from here.

- The elastic material is soft and should be thickened when printing.

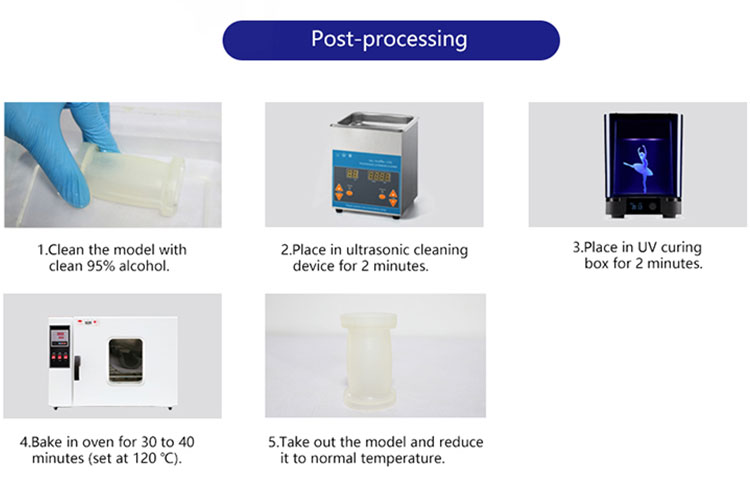

- After printing, clean it with alcohol and solidify, then put it in the oven to heat after solidification, the performance will be better.

Request a quote?

We’re here to help you find the best, most cost‑effective solution for you.