Jewelry casting resin (#3122)

This is an entry-level jewelry resin that can be directly cast in lost wax. You can use it for testing and learning.

- Easy to cast, suitable for more gypsum powder

- Faster print speed

- High liquidity, high secondary utilization rate

- Safe & Not smelly

Getting Started with Casting Resins

This is an entry-level jewelry resin that can be directly cast in lost wax. You can use it for testing and learning.

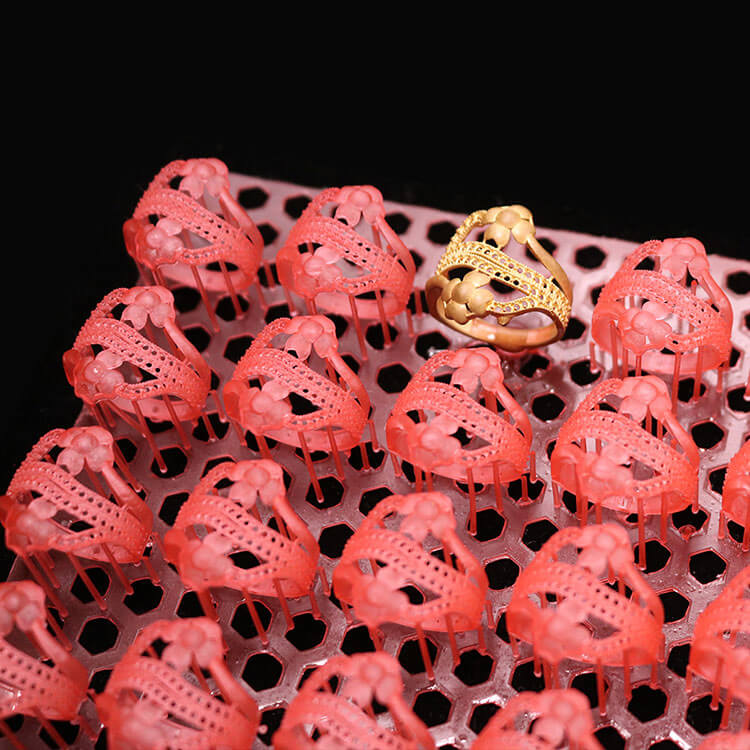

High precision

The jewelry model 3D printed with 3122 resin has a smooth surface and shows high precision details.

Accurate printing

With 30% wax filling and low shrinkage rate (<1%), small holes of 0.5 mm can be printed accurately.

Good fluidity

This resin has low viscosity; it is easy to clean and has high gloss after cleaning.

Temporary Crown Application

How to Make and Use 3D Printed Temporary Crown Resin >>

The application process of 3D printing temporary dental crowns using resin involves the following steps:

- Scanning the patient’s teeth and gums using a 3D scanner or dental impressions.

- Designing a 3D model of the tooth using CAD/CAM software based on the scans.

- Slicing the 3D model into layers and preparing it for printing.

- Printing the model layer by layer using dental crown resin.

- Washing and curing the printed model to remove excess resin and harden it.

- Polishing the crown to give it a smooth texture.

- Applying a layer of glaze or enamel to the crown for added protection and natural appearance.

- Disinfecting the crown to ensure it is safe for use.

- Fitting the temporary dental crown onto the patient’s tooth.

- Temporarily cementing the crown onto the tooth until a permanent crown can be made and installed.

Specifications of Jewelry Casting Resin(3122)

Project Content Data value Testing method Physical and chemical properties

(before curing)color red/yellow/emerald green Viscosity 200-350 cps(25℃) ASTM D1084 Density 1.05±1.1g/cm³ ASM D1875 flash point 90-130℃ Physical and chemical properties

(after curing)Shrinkage <1% Hardness 80A-40D ASTM D2240 tensile Strength 15-25 MPa ASTM D5041 ignition temperature 350℃ modulus of elasticity 300-350MPa Breaking strength 20-25MPa elongation 30-50%

Jewelry Casting Resin Print Samples

Enable 3D Digital Production