BPA Free

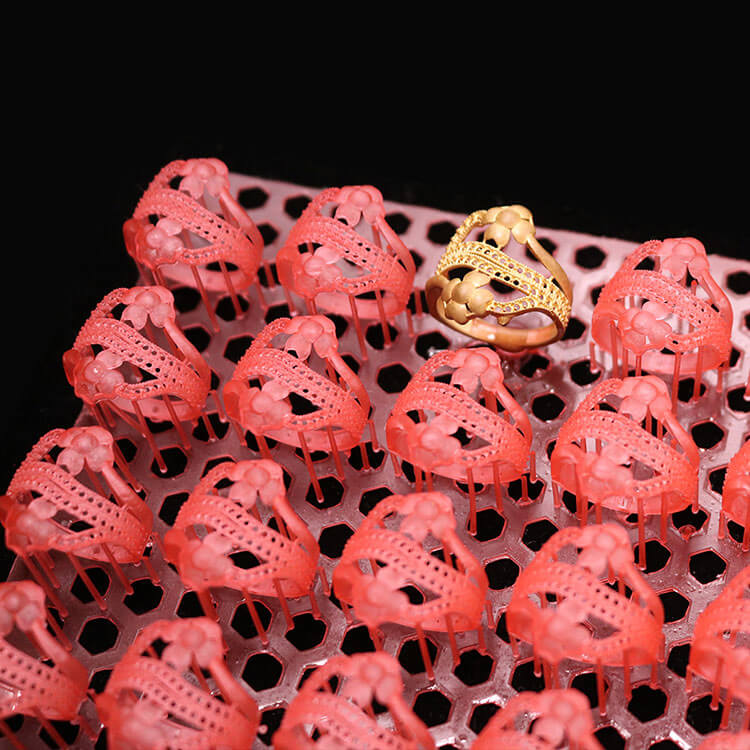

Jewelry casting resin(#3122)

- Easy to cast, suitable for more gypsum powder

- Softer than 311C casting resin

- Faster print speed

- High liquidity, high secondary utilization rate

- Safe & Not smelly

C6H6 Free

Features of Jewelry Casting Resin(3122)

It is an excellent resin material for 3D printing jewelry models.

Perfect casting

3122 resin can be used for lost wax casting.

Clear burning.

No ash. No residue.

Low shrinkage and fixed shape and size.

High fineness of smooth surface spare parts.

High precision

The jewelry model 3D printed with 3122 resin has a smooth surface and shows high precision details.

Accurate printing

With 30% wax filling and low shrinkage rate (<1%), small holes of 0.5 mm can be printed accurately.

Good fluidity

This resin has low viscosity; it is easy to clean and has high gloss after cleaning.

Specifications of Jewelry Casting Resin(3122)

Project Content Data value Testing method Physical and chemical properties

(before curing)color red/yellow/emerald green Viscosity 200-350 cps(25℃) ASTM D1084 Density 1.05±1.1g/cm³ ASM D1875 flash point 90-130℃ Physical and chemical properties

(after curing)Shrinkage <1% Hardness 80A-40D ASTM D2240 tensile Strength 15-25 MPa ASTM D5041 ignition temperature 350℃ modulus of elasticity 300-350MPa Breaking strength 20-25MPa elongation 30-50% - The secondary curing time of casting resin is required to be long.

- The secondary curing time affects whether the resin can burn out, because it is adjusted according to the actual effect.

Request a quote?

We’re here to help you find the best, most cost‑effective solution for you.