Surgical Guide Resin(#3165)

- Biocompatible resin

- Easy to peel off the support by hand

- Low shrinkage, stable storage, no deformation and shrinkage after curing

- High hardness with some toughness

- Disinfected with iodine volts, no irritating odor

- UV curing wavelength: 405nm

Safe for surgical guide

The surgical guide resin has undergone rigorous testing and fully meets the dental requirements for part quality, precision and performance.

Precise fit to the teeth

Combine strength and toughness. Strength can withstand force without deforming, while toughness can withstand force without fracturing.

Precise fit to the teeth

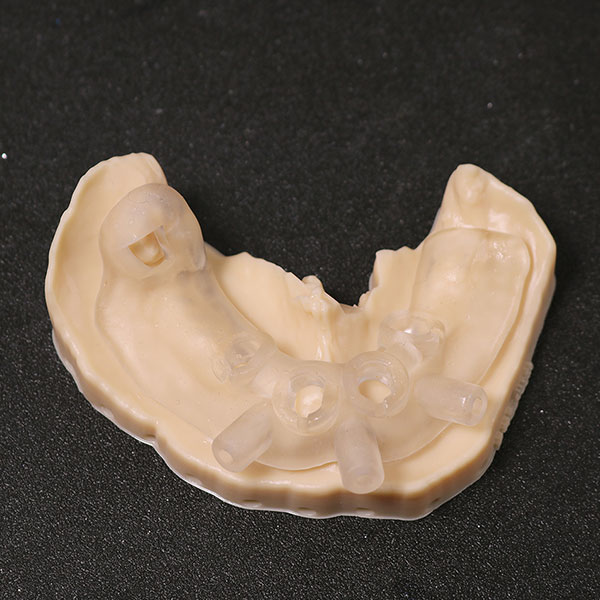

The guide plate printed with 3165 resin has accurate hole position, high hardness and toughness; it can easily install the guide ring and withstand the mechanical impact of surgery.

Low water absorption

Water absorption rate is less than 0.5%. For post-sterilization, the surgical guide is soaked in water containing iodophor for 30 minutes and will not absorb water and become soft or damaged.

Surgical Guide Application

How to Make and Use 3D Printed Surgical Guide Resin >>

The application process of 3D printed surgical guides involves the following steps:

- The surgeon and medical professionals use advanced imaging techniques such as CT scans or MRI to create a 3D model of the patient’s anatomy.

- Using specialized software, the surgical team designs a custom surgical guide that fits the patient’s anatomy perfectly and helps plan the surgical procedure accurately.

- The digital design is then sent to a 3D printer, which uses medical-grade materials to produce the surgical guide with high precision.

- The 3D printed surgical guide is thoroughly cleaned and sterilized to ensure it meets the highest standards of safety and cleanliness.

- During the actual surgery, the 3D printed surgical guide is used by the surgeon as a precise tool to navigate and execute the planned procedure with optimal accuracy.

Specifications of Surgical Guide Resin(3165)

Content Data value Testing method Viscosity 330-350cps(25℃) ASTM D1084-1997 Density 1.15 ASM D1875-69(1980) Shrinkage <0.5% Capillary method Hardness 78D ASTM D2240-05(2010) Water absorption 0.50% ASTM D570 Bending strength 65MPa ASTM D1781 Transmittance >80% ASTM D747 Biocompatibility TEST PASS ISO10993-1/ISO10993-10 Six steps:

Part removal, rinsing, drying, post-curing, support removal, and polishing.Alert:

1. Post-curing time and temperature can lead to suboptimal mechanical and biocompatibility. Please find the right curing time.

2.Disinfection method for the guide plate: Firstly, disinfection by soaking in iodophor solution for 30 minutes, then deiodination by rinsing with medical alcohol or physiological saline.

3.In the data layout, the hole position of the guide ring is kept as vertical as possible to ensure the accuracy of the size.

4.If the hole collapses, It can be reamed by using a drill bit later.

5.Minimum wall-thickness:2mm

Surgical Guide Resin Print Samples

Enable 3D Digital Production