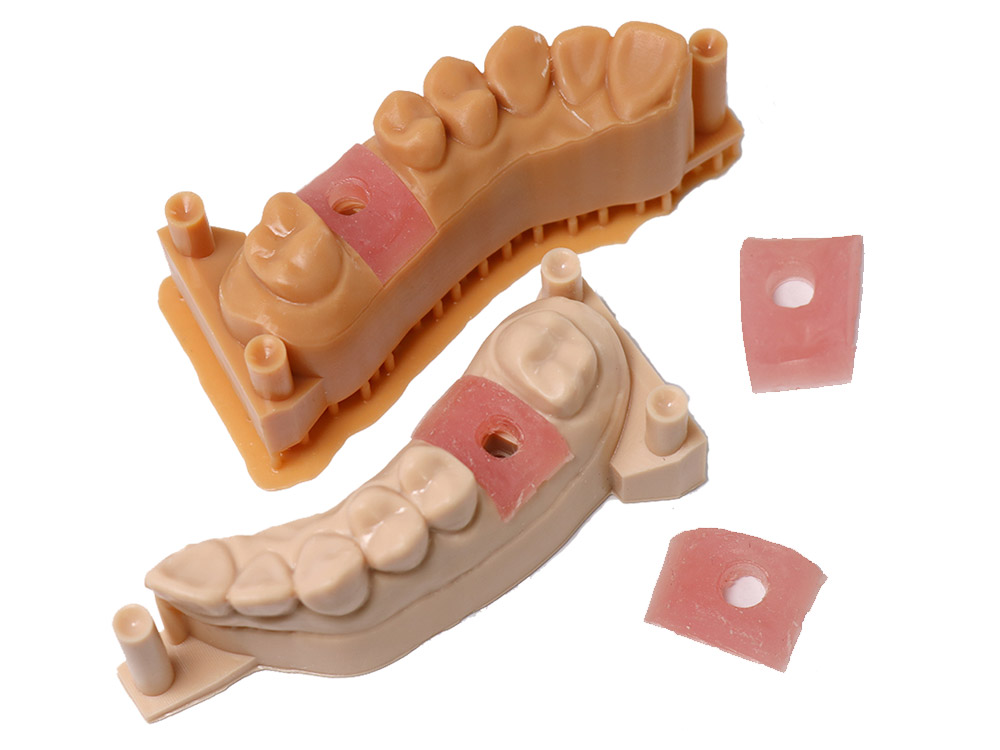

3D printed Gingival mask

Print more for less. Empower your dental business.

IFUN3D develops innovative and cost‑effective 3D printing solutions that meet desired criteria for dental clinics and dental labs. High-pixel LCD 3D printers and Biocompatible 3D-resins. Let’s serve more patients well.

LCD 3D-printing technology, also known as MSLD, is one of resin 3D printing technologies. It uses an LED array as its light source, shining UV light through an LCD screen and displaying a single layer slice as a mask. The more pixels the LCD printer has, the better the print quality.

LCD = liquid-crystal display; MSLD = Masked Stereolithography ;