HP-J800

This is a high-powered secondary curing device that promotes thorough curing of wax model jewelry, resulting in superior casting outcomes.

- The curing power is up to 800 watts, the model is more completely cured, and the casting efficiency and quality are improved.

- Necessary high-power curing box for white wax resin.

- The curing box is also compatible with more casting resins, including IFUN’s 300H, 500B, etc.

- Casting effect can be improved by adopting dry mode to remove excess moisture in the mold.

- Large curing space (310*358*170mm), can put 6 versions of 10.1-inch models at one time, efficient batch curing models, significantly saving labor and time costs.

HP-J800 Supporting Application

How to Make Wax Jewelry

Creating wax molds for jewelry using a 3D printer involves the following steps:

Model Design: Start by designing the jewelry model using computer-aided design (CAD) software or acquire a pre-made digital design.

Import the Model: Import the digital model into the 3D printing software for further adjustments.Add support structures in the software to stabilize the model during printing and make it easier to remove after.Set the printing parameters, including layer height, print speed, and temperature, to achieve high-quality wax molds.

Initiate Printing: Start the 3D printer to produce the jewelry model layer by layer using wax material.

Cool and Solidify: After printing, allow the wax model to cool and solidify to ensure structural integrity.

Remove Support Structures: Carefully remove the support structures without damaging the wax model.

Refinement: Perform any necessary post-processing, such as fine-tuning the surface finish.

Casting: Finally, use the wax model for jewelry casting, typically through the investment casting process, to create the final metal jewelry piece.

These steps outline the key processes for using a 3D printer to create wax molds for jewelry, ensuring precision and quality in the final product.

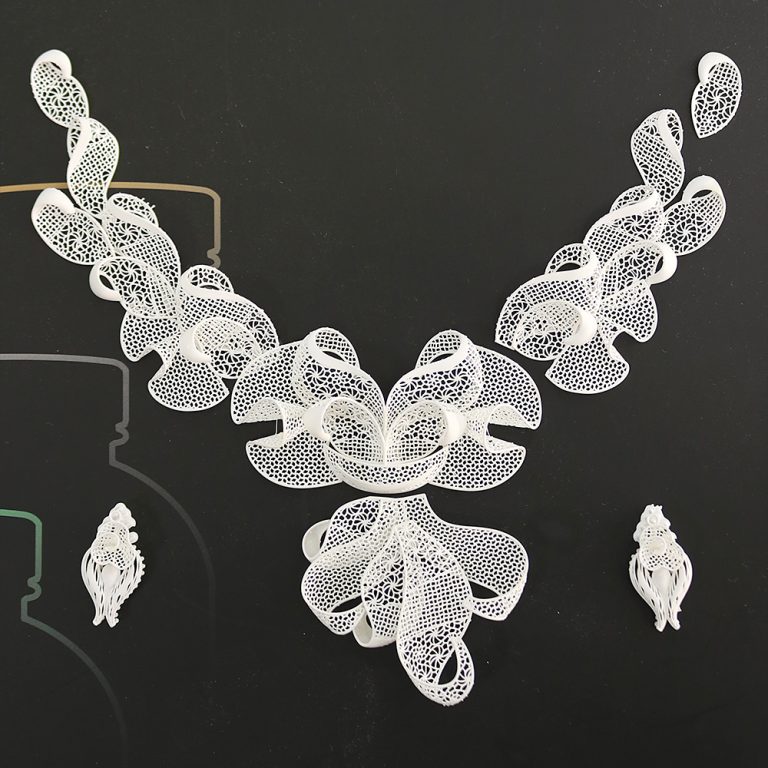

HP-J800 Cured Sample

you may also need these machines

Dent Giant

This high-precision, high-efficiency dental model 3D printer guarantees batch stability

Build Size 218*128*140mm

Printing Speed 50mm/h(max)

Accuracy ±29μm

Resolution 7680*4320(8k)

Packing Weight 52kg/78kg

Packing size 400*400*580mm

Gold Giant 12k

High precision, large size dental HD industrial printer

Build Size 208*128*220mm

Printing Speed 50mm/h(max)

Accuracy ±19μm

Resolution 11520*5120(12k)

Packing Weight 37.5kg

Packing size 580*580*1030mm

Mini Giant Pro – J

Small size fast 3D printer for dental,Small body, big power

Build Size 143*89*150mm

Printing Speed 55mm/h(max)

Accuracy ±35μm

Resolution 4098*2560(4k)

Packing Weight 21kg

Packing size 400*400*580mm

Enable 3D Digital Production