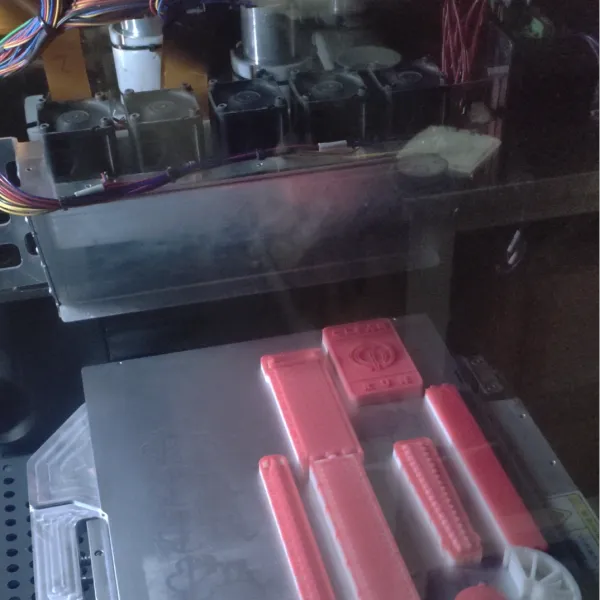

High-Precision Wax 3D Printer for Jewelry Investment Casting

Achieve 2μm precision with our industrial wax 3D printer. Large build volume, 15μm layers, and ash-free burnout for high-volume jewelry investment casting.

Get A QuoteWhy Choose Our Wax Jetting Technology

Massive Build Volume

A spacious 410 x 206 x 157mm platform allows for full-bed printing of intricate rings and pendants in just 24 hours.

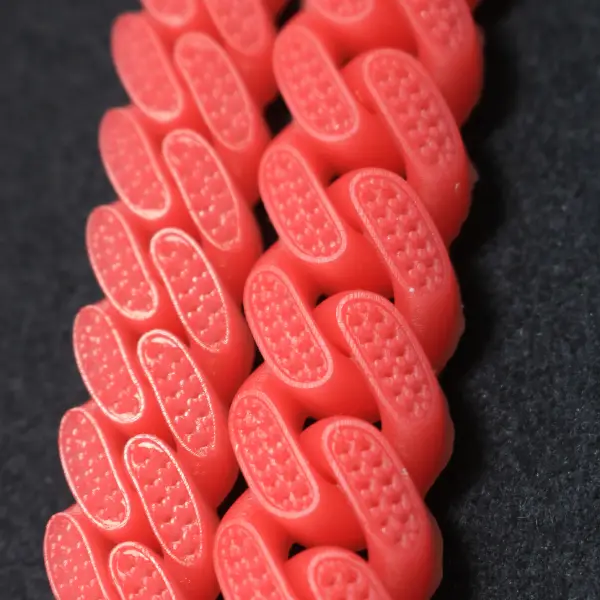

Ultra-High Resolution

Featuring a 2900 x 2900 x 1700 DPI resolution and 15μm layer thickness for smooth surfaces that eliminate manual polishing.

Advanced Wax Formula

Our proprietary wax offers the perfect balance of hardness and flexibility, supporting complex 0.12 mm filigree structures.

Zero-Mold Workflow

Direct-to-casting technology reduces production costs by 30% and significantly shortens time-to-market for new collections.

Technical Specifications

Engineered for the rigorous demands of the jewelry manufacturing industry.

Technology

Multi-Jet Printing (MJP)

Build Envelope

410 × 206 × 157 mm

XYZ Accuracy

Layer Thickness

15μm (Adjustable)

Print Resolution

2900 × 2900 × 1700 DPI

Surface Quality

Ra 6.3 - 3.2

Nozzle Configuration

Triple-Nozzle System (Xaar 3)

Material Specs

1.5kg Base Wax / 1.5kg Support Wax

File Formats

STL, SLC, JCAD, MATRIX

Machine Weight

450 KG

Designed for Master Jewelers

Whether you are casting in gold, silver, or platinum, our printer ensures residue-free burnout and perfect dimensional stability.

"From Digital Design to Casting-Ready in Hours"

Compatible with industry-standard software like Matrix and JCAD. Experience the freedom of 24/7 industrial-grade production with Ubuntu-driven stability.