Pressure Casting Resin (#3123)

Ceramic like prototypes surface, smooth anddelicate, not easytostick to silicone moldseasy to demould after pressing

- Fast Curing Speed

- Easy Demoulding

- High Hardness

- High precision

- High Temperature Resistance

Fast Curing Speed

Smoothing surface: it only takes 2s per layer on 4K Mono LCD printers.

High Hardness: 85D

No deformation after pressing; easy to print small details. To 3D print animation models, dolls, avatar sculptures, etc.

Easy To Release

The finished product is similar to ceramic surface, smooth and delicate; not easy to adhere to the silicone mold, easy to release.

High Precision

Smooth surface, clear sharp angles, excellent detail expression, low shrinkage, and can be assembled accurately

Pressure Casting Resin Application

How to Make and Use 3D Printed Pressure Casting Resin >>

The application process of 3D printing temporary dental crowns using resin involves the following steps:

- Scanning the patient’s teeth and gums using a 3D scanner or dental impressions.

- Designing a 3D model of the tooth using CAD/CAM software based on the scans.

- Slicing the 3D model into layers and preparing it for printing.

- Printing the model layer by layer using dental crown resin.

- Washing and curing the printed model to remove excess resin and harden it.

- Polishing the crown to give it a smooth texture.

- Applying a layer of glaze or enamel to the crown for added protection and natural appearance.

- Disinfecting the crown to ensure it is safe for use.

- Fitting the temporary dental crown onto the patient’s tooth.

- Temporarily cementing the crown onto the tooth until a permanent crown can be made and installed.

Specifications of Pressure Casting Resin(3123)

Project Content Data value Testing method Physical and chemical properties

(before curing)color orange/cuticolor Viscosity 200-400 cps(25℃) ASTM D1084 Density 1.08g/cm³ ASM D1875 flash point 110℃ Physical and chemical properties

(after curing)Linear Shrinkage <1% Hardness 70-85D ASTM D2240 Bending modulus 3000-3800MPa Thermal deformation 120-140℃ Elongation 30-50% Breaking strength 60-80MPa strength rate 8~10%

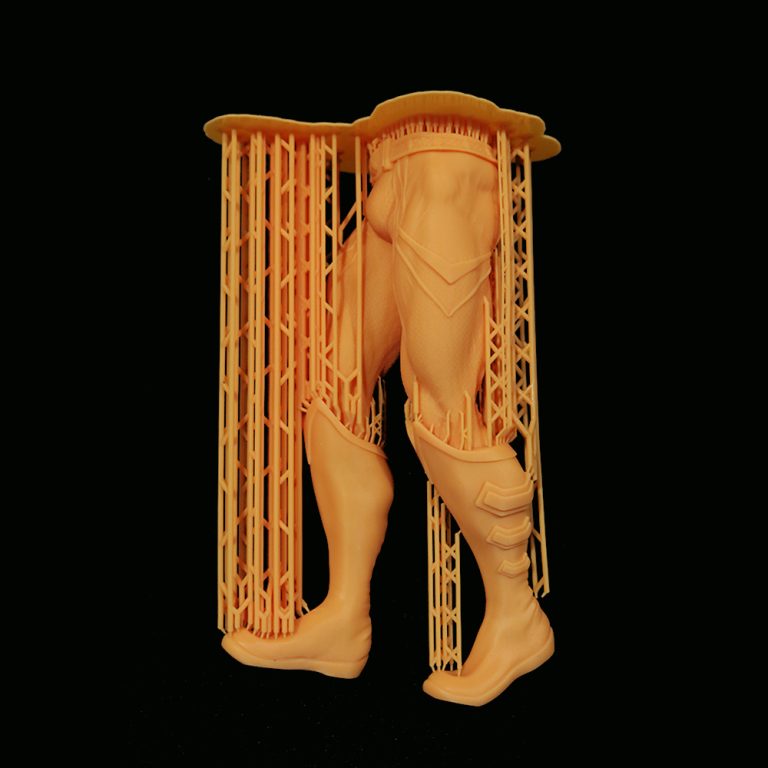

Pressure Casting Resin Print Samples

Enable 3D Digital Production