The integration of 3D printing into metal casting has transformed traditional foundry processes. By enabling rapid, precise, and cost-efficient mold production, 3D printing metal casting opens new possibilities for designers, engineers, and manufacturers alike. In this article, we explore the current state of metal casting from 3D print, innovative technologies, and how 3D printing molds for casting metal offer distinct advantages for prototyping and small-scale production.

Why Use 3D Printing for Metal Casting?

1. Simplified Production Workflow

Traditional casting methods involve multiple steps—designing, creating wax or foam patterns, building sand molds, and post-processing. In contrast, 3D printer metal casting streamlines the workflow by eliminating the need for tooling and manual mold-making. CAD designs can be directly converted into patterns or even sand molds using 3D printers.

2. Faster Prototyping & Iteration

One of the biggest benefits of 3D printing metal casting is rapid prototyping. You can move from design to physical mold or pattern within a few hours, significantly reducing development cycles—ideal for custom components or low-volume production.

3. Increased Design Freedom

Additive manufacturing allows for complex geometries, intricate internal channels, and lightweight structures that are impossible or expensive with traditional mold-making. This freedom is critical in industries such as aerospace, automotive, and jewelry.

How 3D Printing Is Used in Metal Casting

A. Printing Patterns for Investment Casting

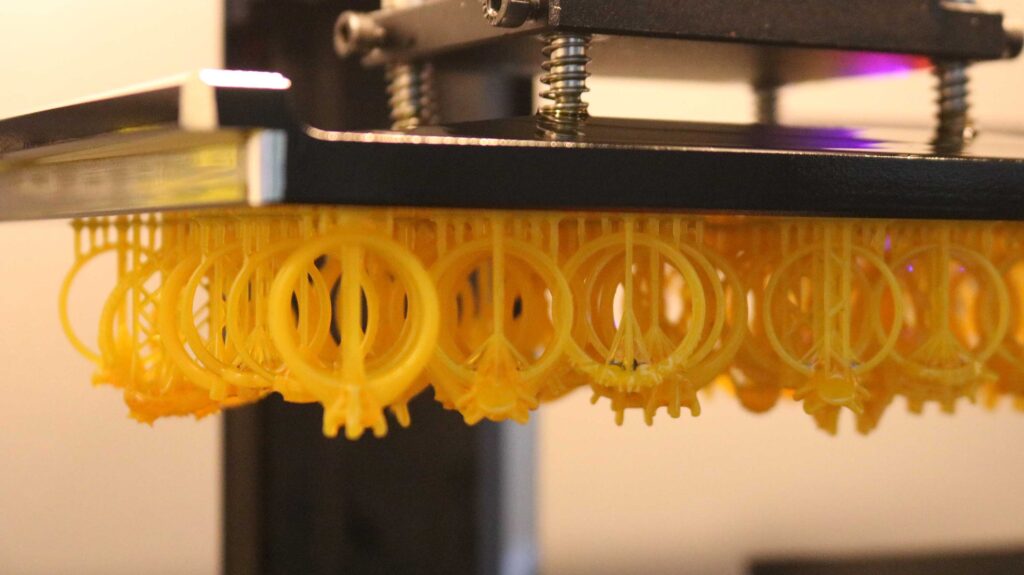

A common approach to metal casting from 3D print is to 3D print wax-like patterns for lost-wax casting. These patterns are burnt out in the kiln, leaving a mold cavity ready for molten metal. This is widely used in jewelry and dental casting.

B. Direct Printing of Sand Molds or Cores

Technologies like binder jetting allow for the direct production of sand molds and cores. This process enables large-scale components to be cast without pattern tooling and is increasingly used in automotive and industrial parts manufacturing.

C. 3D Printing High-Temperature Molds

With advancements in resin-based and ceramic-filled materials, 3D printing molds for casting metal is now possible even for small-batch aluminum or bronze casting. These molds can withstand higher pouring temperatures and maintain dimensional stability.

Cutting-Edge Technologies in 3D Printer Metal Casting

- Voxeljet & ExOne: Known for large-format binder jetting sand molds and cores.

- SLA/DLP Resin Printers: Produce high-detail castable patterns using wax-like or burnout-friendly resins.

- HP Metal Jet & EOS: Offer direct metal 3D printing but can complement traditional casting for hybrid applications.

Cost-Benefit in Small-Scale Production

While high-volume casting may still favor traditional tooling, 3D printing metal casting shines in short runs. Benefits include:

- No tooling cost: Ideal for runs under 1000 units.

- On-demand manufacturing: Perfect for obsolete parts or repair components.

- Customization: Enables mass customization with minimal production delay.

- Material savings: Topology-optimized parts reduce waste.

According to industry data, 3D printing can cut total costs by 30–70% in low-volume production compared to conventional casting.

Challenges to Consider

- Material limitations: Not all metals or alloys are suitable for every 3D printed mold type.

- Thermal resistance: Resin molds may degrade under high pouring temperatures.

- Post-processing: Cleanup and surface finishing may still be needed for final cast parts.

Despite these, the evolution of printable materials and hybrid workflows is rapidly overcoming such barriers.

Conclusion

From rapid prototyping to custom metal parts, metal casting from 3D print is no longer a futuristic concept—it’s an efficient, scalable solution being adopted across industries. By leveraging 3D printer metal casting methods, manufacturers gain speed, flexibility, and precision that traditional processes struggle to offer. Whether using 3D printing molds for casting metal or direct pattern production, the synergy between additive manufacturing and metal casting is reshaping modern fabrication.