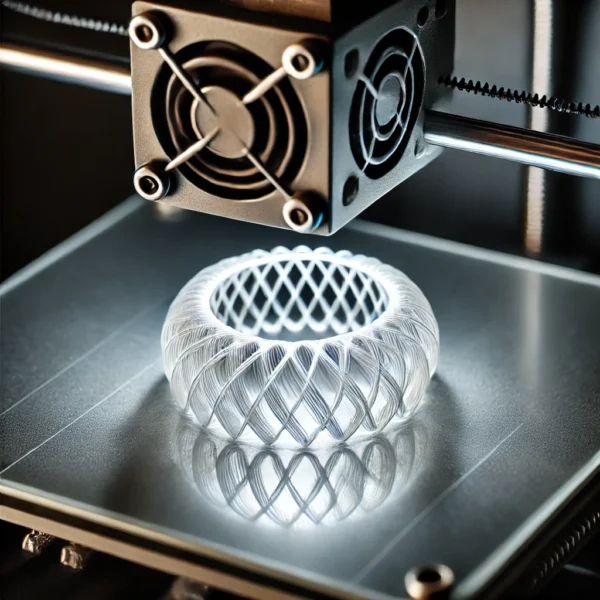

In the world of 3D printing, clear PLA has gained popularity for its accessibility and eco-friendliness. For jewelry designers and manufacturers, using clear 3D printer filament can open up new possibilities. But how does PLA clear filament compare to clear resin (SLA/DLP)? This guide explores the benefits, limitations, and best practices for using clear filament for 3D printers in jewelry design.

What Is Clear PLA?

Clear PLA filament is a biodegradable plastic made from renewable resources like cornstarch. It is commonly used in 3D printing clear filament projects because of its ease of use and compatibility with FDM printers.

Key Properties of Clear PLA:

- Eco-friendly:Made from plant-based materials, PLA clear filament is biodegradable.

- Low printing temperature:Works well with most desktop FDM 3D printers.

- Good natural transparency:Can achieve a semi-transparent look with proper settings.

- Rigid but brittle:Strong but can snap under pressure.

- Low heat resistance:Softens at around 60°C.

Clear PLA vs. Clear Resin: Which One to Use?

Feature | Clear PLA (FDM) | Clear Resin (SLA/DLP) | Comparison Highlights |

Print Quality | Good, but visible layers | High, smooth surface finish | Clear Resin offers superior surface finish compared to Clear PLA. |

Transparency | Semi-clear, post-processing required | Naturally higher clarity | Clear Resin has better inherent transparency without extensive post – processing. |

Durability | Hard but brittle | Tough but prone to UV damage | Both have different durability trade – offs; Clear PLA is brittle, while Clear Resin is UV – sensitive. |

Post – Processing | Sanding, polishing, coatings | UV curing, polishing, coating | The post – processing for Clear Resin involves UV curing which is not required for Clear PLA. |

Cost | Low (affordable printers & filament) | Higher (specialized resin & printers) | Clear PLA is more cost – effective in terms of both printer and material. |

Eco – Friendliness | Biodegradable, safe to handle | Some resins are toxic | Clear PLA is more eco – friendly and safer to work with compared to some Clear Resins. |

Best for | Concept models, light jewelry | High – detail prototypes, casting molds | Clear PLA suits basic models, while Clear Resin is ideal for high – precision applications. |

Applications of Clear PLA in Jewelry Design

- Jewelry Prototyping & Concept Validation

Jewelry designers can use clear PLA filament to test new designs before final production. While 3D printing clear filament does not achieve glass-like transparency, it allows designers to visualize shapes, sizes, and layering effects.

- Transparent Decorative Jewelry

With proper post-processing, clear PLA prints can be used to create earrings, pendants, and bracelets with a frosted glass look. Although it won’t match the clarity of clear resin prints, it offers an affordable alternative.

- Smart Jewelry & Custom Accessories

Designers creating wearable technology can use clear PLA 3D prints for casings and enclosures, integrating LEDs or sensors inside transparent elements.

Enhancing the Transparency of Clear PLA

To maximize the clarity of 3D printing clear filament, follow these techniques:

- Reduce Layer Height– A lower layer height (0.1mm or less) improves transparency.

- Use a High-Quality Nozzle– A smooth extrusion improves optical clarity.

- Post-Processing Methods:

- Sanding and polishing (progressively finer grits)

- Clear epoxy or acrylic coatings

- Heat treatment (careful exposure to warm air)

How to 3D Print Clear PLA Jewelry?

Clear PLA is a popular 3D printing material suitable for concept prototypes, transparent decorative elements, and even parts of smart jewelry casings. However, achieving high transparency and fine details requires careful adjustments.

- Choosing the Right Clear PLA Filament

Not all clear PLA filaments offer the same transparency. Some brands add matte fillers, resulting in a semi-transparent effect. Look for high transparency clear PLA filament to achieve better optical clarity.

- Optimizing 3D Models to Reduce Layer Lines

Jewelry models should be designed with transparency in mind:

- Avoid complex hollow structures– too many supports may reduce clarity

- Use smooth transitions– to minimize light refraction between layers

- Increasing wall thickness– ultra-thin models may cause optical distortions

- Print Settings for Enhanced Transparency

- Layer height:1mm or lower to reduce visible layers

- Print temperature:210-230°C for full filament fusion and fewer air bubbles

- Infill pattern:“linear” or “concentric” to minimize light scattering

- Print speed: Reduce to 30-40mm/s for smoother extrusion

- Post-Processing for Glass-Like Clarity

Even with optimized print settings, the result will likely be semi-transparent rather than fully clear. To further enhance transparency:

- Sanding: Use 400 to 2000 grit sandpaper for gradual surface refinement

- Clear coat spray: Apply a transparent UV-resistant spray

- Epoxy resin coating: A thin layer can remove layer lines and improve gloss

- Polishing: Some PLA brands respond well to acetone vapor smoothing or manual polishing

- Using Clear PLA for Smart Jewelry Design

Clear PLA is ideal for LED jewelry, transparent casings, and light-reflective accessories. Examples include:

- Transparent pendants with embedded LED lights for better illumination

- Clear covers that make smart chips visible

- UV-reactive coatings for color-changing effects in jewelry

Clear PLA vs. Other Transparent 3D Printing Materials

If clear PLA does not provide the level of transparency needed for jewelry, consider alternative materials:

Material | Transparency | Durability | Best Use Cases | Key Advantages |

Clear PLA | Semi-transparent | Brittle | Budget-friendly prototypes | Cost-effective for quick prototyping |

Transparent PETG | High transparency | Strong & flexible | Lightweight, durable jewelry | Combines transparency with strength and flexibility |

Clear Resin (SLA Printing) | Glass-like | High precision | Lost-wax casting, fine jewelry | Exceptional transparency and precision for detailed work |

Transparent PC (Polycarbonate) | Extremely clear | High heat resistance | Engineering-grade jewelry, smart casings | High clarity and heat resistance for demanding applications |

To successfully 3D print clear PLA jewelry, choose high-transparency PLA filament, optimize model design and print settings, and apply post-processing techniques. If you require higher transparency, SLA resin or PETG may be better options.

The Future of Clear PLA in Jewelry Making

As material innovations improve clear PLA 3D printing filament, its applications in jewelry design will expand. Advances in post-processing and material blends could enhance its transparency and durability, making it an even stronger competitor to clear resin for certain applications.

Clear PLA filament is a versatile, eco-friendly option for jewelry prototyping and decorative designs. While it cannot fully replace clear resin for high-precision applications, it provides an affordable and accessible alternative for designers experimenting with transparency. By optimizing print settings and applying post-processing techniques, clear 3D print filament can become a valuable tool in modern jewelry design.