3D printing technologies have revolutionized manufacturing, and two prominent methods for resin-based printing are Continuous Liquid Interface Production (CLIP) and Traditional LCD 3D Printing. While both fall under the umbrella of vat photopolymerization, their underlying principles and resulting advantages are distinct. Understanding these differences will help you appreciate the unique benefits our DLP 3D printers offer.

1. Core Principle Comparison

1.1 CLIP Technology Principle

CLIP’s fundamental innovation lies in its “oxygen-permeable window” (often made of Teflon) at the bottom of the resin tank. This window is transparent to UV light but also allows oxygen to permeate into the resin, creating a very thin “Dead Zone”.

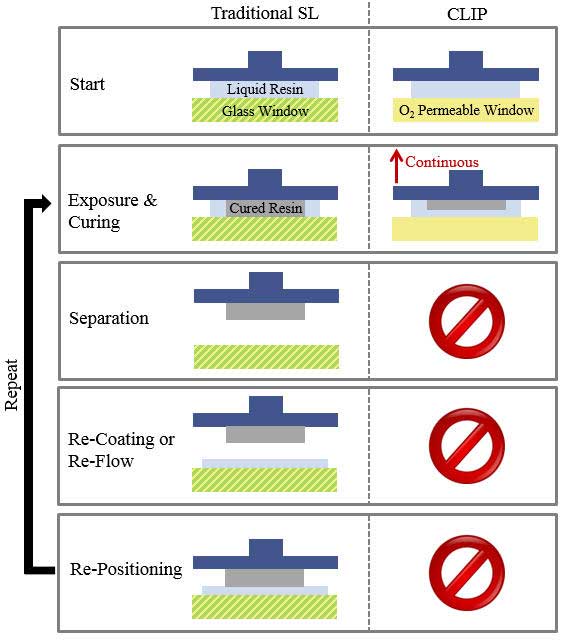

- Oxygen Inhibition & Dead Zone: Within this dead zone, oxygen inhibits the photopolymerization reaction, keeping the resin in a liquid state. Resin only solidifies rapidly once it’s pulled out of this dead zone. This ingenious design enables a continuous, uninterrupted printing process, completely eliminating the traditional layer-by-layer peeling steps.

- Dynamic Equilibrium Control: A dynamic balance is maintained within the dead zone between UV light (which activates curing) and oxygen (which inhibits the reaction). By precisely controlling the oxygen permeation rate and light intensity, CLIP achieves a continuously moving solidification interface, allowing for smooth, uninterrupted vertical pulling of the object from the resin vat.

1.2 Traditional LCD 3D Printing Principle

LCD technology utilizes a high-resolution Liquid Crystal Display (LCD) screen as a mask for the UV light source (typically 405nm UV LEDs). It works on a discrete, layer-by-layer manufacturing principle:

- Sequential Curing: The LCD screen selectively blocks or allows UV light to pass through for each layer’s cross-section. When UV light hits the photosensitive resin, it cures.

- Interrupted Process: After each layer is cured, the light is momentarily turned off. The build platform then lifts to separate the newly cured layer from the bottom of the resin vat. Fresh resin flows back into the gap, and then the next layer is exposed. This process involves a physical “peel and re-coat” interval for every single layer.

- Time-Consuming Layer Actions: The need for the platform to lift, the cured layer to peel, and new resin to flow and level (sometimes assisted by a scraper or gravity) adds significant time to the overall printing process.

processes(SLA/DLP)

2. Core Advantages Comparison

2.1 Print Speed: CLIP’s Revolutionary Lead

| Indicator | CLIP Technology | LCD Technology | Key Breakthrough |

| Theoretical Speed | Continuous, no layer interruptions; 10-100x speed increase | Limited by number of layers and re-coating time | CLIP’s dead zone eliminates the “peel-and-recoat” cycle, enabling true continuous liquid interface production (akin to casting). LCD is confined to discrete layering. |

| Real-world Example | Prints a sphere in just 6.5 minutes (traditional takes hours) | Small to medium objects can still take several hours | |

| Speed Limitation | Only limited by polymerization rate and resin viscosity | Directly proportional to the number of sliced layers |

2.2 Formation Accuracy: CLIP Achieves Micro-Level Precision

- CLIP:

- Lower Theoretical Layer Thickness Limit: The dead zone allows for incredibly thin cured layers (down to 20μm or less). The continuous exposure also minimizes layer-to-layer misalignment, resulting in exceptionally smooth surfaces with no visible stair-stepping effect.

- Isotropic Mechanical Properties: Continuous curing eliminates weak inter-layer bonds, significantly enhancing the mechanical strength and durability of the printed part. This means parts perform more like injection-molded components.

- LCD:

- Resolution Dependent: While improving with 4K/8K screens, accuracy is typically around 100μm. However, the inter-layer peeling process can introduce micro-deformations.

- Visible Stair-Stepping: Parts often exhibit noticeable layer lines, requiring post-processing like sanding to achieve a smooth finish.

2.3 Material Compatibility: LCD Offers More Flexibility

| Technology | Compatible Resin Types | Limitations |

| CLIP | Primarily free-radical polymerization resins (acrylates) | Requires low viscosity (<300cP) to ensure proper flow and self-leveling |

| LCD | Free-radical and epoxy resins are generally compatible | No specific viscosity requirements beyond basic handling |

Reason: CLIP’s reliance on the oxygen inhibition effect (to which only acrylates are sensitive) and the absence of a scraper/re-coating mechanism necessitates self-leveling, low-viscosity resins. LCD doesn’t have these specific constraints.

2.4 Application Scenarios Differentiation

| Technology | Applicable Scenarios | Typical Use Cases | Deep Difference |

| CLIP | Industrial-grade functional parts: automotive, biomedical, elastomers (e.g., shoe midsoles) | Heat-resistant resin parts, heart stents | CLIP’s continuous nature and enhanced material strength make it ideal for direct manufacturing of end-use products. |

| LCD | High-precision small parts: jewelry, dental models, miniature prototypes | Dental crowns, casting molds | LCD’s lower cost and high resolution are better suited for rapid prototyping and small-batch precision components where cost is a primary concern. |

2.5 Cost & Technical Complexity

| Dimension | CLIP Technology | LCD Technology |

| Equipment Cost | High (due to oxygen-permeable membrane, precise oxygen control system) | Low (LCD screen replaces expensive lasers/DMD chips) |

| Maintenance Cost | Oxygen-permeable membrane requires periodic replacement | LCD screens have a limited lifespan (frequent replacement needed) |

| Technical Barrier | Requires precise control of oxygen/light dynamic equilibrium | Mature open-source solutions, simpler operation |

3. Technical Limitations Comparison

CLIP’s Bottlenecks:

- Narrower Resin Selection: Primarily limited to low-viscosity acrylate resins.

- Higher Equipment Cost: Typically starts from around $40,000, making it more suited for industrial applications.

LCD’s Drawbacks:

- Precision Loss Due to Layer Peeling: The peeling action can introduce minor inaccuracies.

- Low LCD Screen Light Efficiency: Only about 10% light transmittance, requiring high-power UV light sources.

4. Conclusion: Technological Positioning & Future Outlook

| Dimension | CLIP Technology | LCD Technology | Key Conclusion |

| Core Value | Industrial mass production, breaks speed-accuracy paradox | Cost-effective precision prototyping | If your goal is production-level efficiency and superior mechanical properties for end-use products, CLIP is a revolutionary choice. If you prioritize cost-sensitive, high-precision applications, LCD offers broader applicability. |

| Development Direction | Multi-material compatibility, larger equipment development | Improving screen lifespan and light efficiency | |

| User Choice | End-product manufacturing, high-performance needs | Education, dental, jewelry, and other precise small parts |

Why This Matters for DLP 3D Printers:

While CLIP is a distinct technology, many of the advantages highlighted for CLIP (like speed, surface quality, and often isotropic properties) are also strong selling points for DLP (Digital Light Processing) 3D printers when compared to LCD. DLP systems, like CLIP, cure an entire layer at once using a projector, leading to faster print times than laser-based systems and often better resolution and light efficiency than LCD. Our DLP printers leverage similar principles to offer you:

- Exceptional speed: By curing full layers quickly.

- High precision and smooth surfaces: Thanks to precise pixel control.

- Reliability: Due to robust light engines and controlled curing.

We believe our DLP 3D printer offer a fantastic balance of speed, accuracy, and versatility for your clients’ needs.