When a dental 3D printer finishes its cycle and the build platform rises, it is easy to mistake the gleaming dental model or surgical guide for a finished product. However, in the precise world of digital dentistry, the printing process is merely the beginning.

Fresh off the build plate, parts exist in what is technically known as the “Green State.” At this stage, the resin has solidified just enough to hold its shape, but it has not yet achieved the chemical stability required for clinical use. To bridge the gap between a fragile prototype and a certified medical device, one critical process remains: post curing.

This article explores why 3d printing post curing is the heart of the dental workflow, examining the science of polymerization, the necessity of biocompatibility, and the mechanical realities of dental appliances.

1. The Science: From Green State to Full Conversion

To understand why 3d printing post-curing is non-negotiable, we must look at the chemistry. Dental resins cure via a process called photopolymerization. During the printing phase, the printer’s light source initiates this reaction, but it typically only achieves a partial “Degree of Conversion” (DC)—often hovering around 50% to 60%.

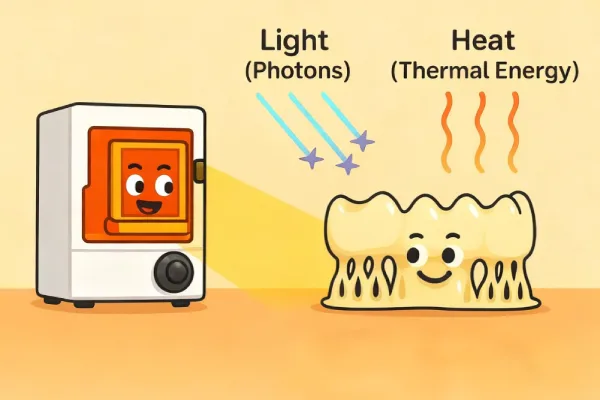

This means nearly half of the monomer chains in the “Green State” part are unreacted and disconnected. Post curing utilizes a combination of specific light wavelengths and heat to drive this conversion closer to completion (often exceeding 90%).

- Light (Photons): Specialized UV/Blue light (typically 405 nm) penetrates the material to excite the remaining photoinitiators, triggering residual monomers to cross-link.

- Heat (Thermal Energy): Heat is a catalyst. It increases molecular mobility, allowing polymer chains to move and find each other to form strong chemical bonds. Research suggests that for many dental resins, maintaining a temperature of approximately 60°C during curing is essential for maximizing flexural modulus.

2. The Workflow: Washing, Drying, and Curing

Effective 3d printing post curing is not just about putting a part in a light box; it is the final step of a strict three-part protocol.

Step 1: Washing

Parts must be thoroughly washed, typically in Isopropyl Alcohol (IPA ≥ 99%), to remove uncured liquid resin from the surface. Failure to wash properly results in a sticky surface and obscured details.

Step 2: Drying

This is often the most overlooked step. Before entering the curing unit, the solvent must completely evaporate. If alcohol remains on the surface during the curing cycle, it can interfere with the light absorption or cause surface cracks and opacity.

Step 3: Post-Curing

The part is exposed to uniform light and heat. Advanced units may use nitrogen environments to eliminate “oxygen inhibition”—a phenomenon where oxygen in the air prevents the outer surface of the resin from curing completely, leaving it tacky.

3. Biocompatibility: The Safety Imperative

For any dental application intended for intraoral use—whether it is a temporary crown, a night guard, or a surgical guide—biocompatibility is the top priority. 3d printing post-curing is the primary mechanism that ensures patient safety.

In their “Green State,” printed parts contain a significant amount of residual monomers. If placed in a patient’s mouth, these unreacted chemicals can leach out into the saliva, posing serious risks:

- Cytotoxicity: Potential damage to oral tissue cells and gingival fibroblasts.

- Sensitization: Allergic reactions, gum irritation, or redness.

- Systemic Toxicity: Long-term health implications from chemical leaching.

Strict Adherence to ISO Standards: proper post curing drives polymerization to a level where residual monomers are negligible. This is the only way to ensure the material meets ISO 10993 (Biological evaluation of medical devices) standards. Without following the manufacturer’s specific Instructions For Use (IFU), the product cannot be ethically classified as biocompatible.

4. Mechanical Mastery: Strength and Accuracy

Beyond safety, 3d printing post-curing dictates the physical performance of the appliance. The difference in mechanical properties between a Green State part and a fully cured part is drastic.

Clinical research indicates that without heat-assisted curing, many engineering resins never reach their maximum strength potential. For example, a surgical guide that is under-cured may be too flexible, leading to deviation during implant drilling.

Comparative Analysis: Green State vs. Post-Cured

| Property | Green State (Uncured) | Post-Cured (Final) | Clinical Impact |

|---|---|---|---|

| Degree of Conversion | ~50-60% | >90% | Determines chemical stability and safety. |

| Flexural Strength | Low | Maximized | Prevents bridges/crowns from snapping under biting forces. |

| Elastic Modulus | Low (Soft) | Optimal Stiffness | Ensures aligners move teeth effectively; prevents guides from bending. |

| Dimensional Stability | Unstable | Stable | Ensures marginal fit and prevents warping over time. |

5. Best Practices for Dental Labs and Clinics

To achieve consistent results with 3d printing post curing, dental technicians must treat the process as a science, avoiding guesswork.

- Match the Equipment: A simple UV lamp designed for nail salons is rarely sufficient for dental resins. Dental materials require curing units with specific wavelengths (UVA/UVB combination) and calibrated intensity to ensure deep polymerization.

- Respect the IFU: Every resin formulation is unique. A model resin might need 10 minutes at room temperature, while a permanent crown resin might require 20 minutes at 60°C. Always consult the manufacturer’s guidelines.

- Avoid Over-Curing: While less dangerous than under-curing, leaving parts in the chamber for excessive periods (e.g., hours) can lead to polymer degradation, yellowing (discoloration), and brittleness.

- Consider the Environment: For high-precision medical devices, using nitrogen-purged curing units or glycerin baths can prevent oxygen inhibition, resulting in a harder, smoother surface finish.

Conclusion

In the digital dental workflow, the printer often gets the attention, but the post curing unit delivers the performance. It serves as the bridge between a raw chemical liquid and a safe, durable medical device.

By understanding the critical role of 3d printing post-curing, dental professionals ensure that their restorations are not only geometrically accurate but also biologically safe and mechanically sound. As the industry continues to advance, adhering to these post-processing standards remains the hallmark of professional digital dentistry.