New 3D Scanning Tech Speeds Up Jewelry Design and 3D Printing at Cooksongold

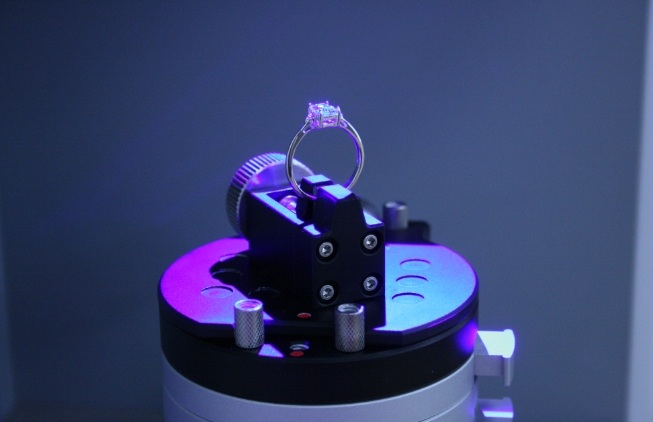

UK-based jewelry supplier Cooksongold is cutting design time in half thanks to a powerful new tool — the Artec Micro 3D scanner.

With this high-precision scanner, the company can now create super-detailed 3D models of jewelry pieces in just 1 to 2 hours. That’s a big leap from the traditional CAD modeling process, which could take 3 to 4 hours for a complex ring — and still might not be perfect.

Olivia Champion, a New Product Development Engineer at Cooksongold, explains it best:

“If it’s a basic ring or something simple, we can scan it in about an hour. We get a few versions, stitch them together, fix any issues, and send the file to the customer. It’s much faster than trying to model it by hand.”

And that’s not just about speed. It’s also about accuracy.

Artec Micro captures tiny details — like engravings or textures — that are hard to recreate manually. That means jewelers and designers can get digital copies that are incredibly close to the real thing.

Better for Custom Work, Better for 3D Printing

This faster process is great news for anyone who needs custom designs or duplicates of handmade jewelry.

Once scanned, the models are saved as editable STL files. These files can be easily adjusted or sent straight to a resin-based 3D printer. That opens up a lot of possibilities — not just for one-off custom jobs, but also for short-run production.

With high-res scans, the details transfer cleanly into the print. That’s especially important for resin 3D printing, where surface quality and fine features matter a lot.

In short: less guesswork, more precision, and much faster turnaround.

A Simple Service for Jewelers and Clients

Cooksongold now offers this 3D scanning as a service. Jewelers or clients just send in their items. The company scans them and returns a ready-to-use digital file.

That file can be printed, modified, or stored for future use. Want to remake a lost earring or tweak a vintage piece? No problem.

This digital workflow helps businesses keep a digital archive of designs. It’s also a great way to protect intellectual property, since exact copies are stored securely.

Tech Keeps Improving

And there’s more on the horizon. Artec has also released the Micro II, which goes even further. It offers 5-micron accuracy and 2-micron repeatability, plus a larger field of view. That means even better results, especially for tiny or complex items.

Sergey Suhovey, Chief Experience Officer at Artec 3D, says it best:

“Micro helps jewelry makers streamline their work, offer more to customers, and save time. It’s amazing to see it making such a big impact.”

Why It Matters for 3D Printing

This kind of scanning tech makes 3D printing smarter and faster. No more slow CAD modeling. No more detail loss. Just scan, edit, and print.

For industries like jewelry, dental, or even small-scale manufacturing, this is a game-changer.

It bridges the gap between handmade artistry and digital precision — making 3D printing more powerful, more personal, and more efficient than ever.