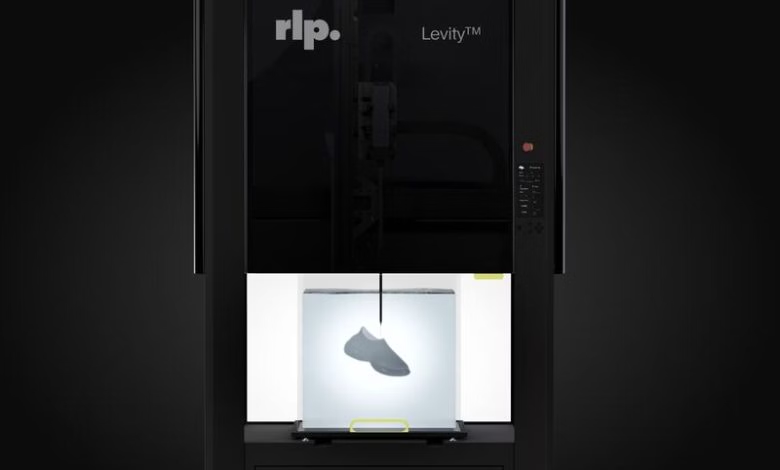

Rapid Liquid Print, a company spun out of MIT, unveils Levity™—a gravity-defying, sustainable 3D printing platform for elastomers

Rapid Liquid Print (RLP), an innovative startup incubated by MIT’s Self-Assembly Lab, has officially announced the upcoming launch of its groundbreaking 3D printing platform, Levity™, slated for commercial release in 2026. Leveraging a reusable water-based gel as its printing medium, this revolutionary system enables true support-free printing in suspension, positioning Levity as one of the most disruptive 3D printing technologies to watch in the coming year.

“We didn’t just build a machine over the past five years—we’ve reimagined the logic of manufacturing.”

— Schendy Kernizan, Co-founder & CEO of RLP

No More Supports: Just Print, Rinse, and Done

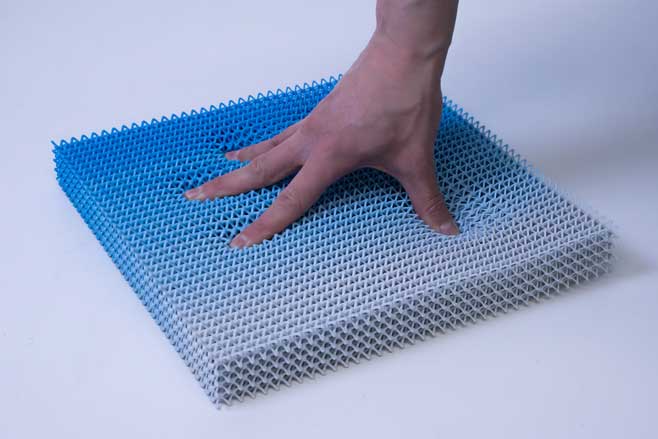

Unlike traditional 3D printing processes, Levity utilizes a unique liquid suspension printing method, where parts are printed directly within a water-based gel medium, forming “in mid-air.” Once printing is complete, the object is simply rinsed with water, with no supports, curing, sanding, or post-processing required. This approach drastically reduces material waste, labor, and production time.

The suspension gel used during the printing process is non-toxic, environmentally safe, and reusable. Each batch can last for weeks and is biodegradable with no harmful emissions, emphasizing sustainability at every stage.

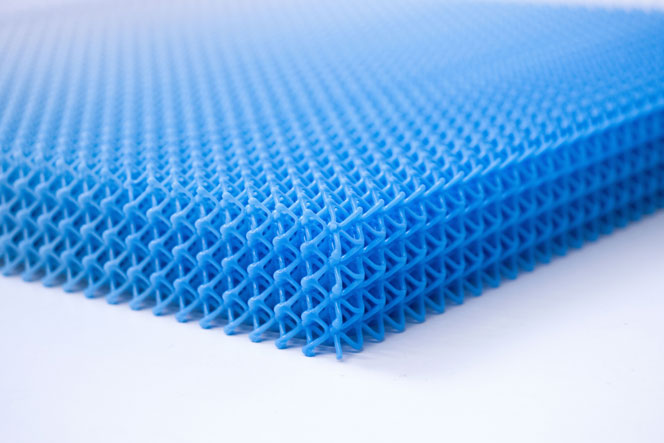

Focused on Elastomers: Functional Parts with Variable Hardness

Levity currently specializes in printing silicone-based elastomer materials, supporting a Shore hardness range from 00-50 to 50A. Thanks to its real-time material blending system, it can even produce multi-durometer parts within a single print job. This makes Levity ideal for applications requiring soft, flexible, and complex geometries, such as medical devices, prosthetics, and wearable technology.

Supported materials include:

- Platinum-cured silicones

- Polyurethanes

- Photocurable elastomers (under development)

VEER™ Slicing System: Rethinking Print Path Logic

Traditional slicing software is incompatible with Levity’s non-planar, spiral-based print paths. In response, RLP developed VEER, a proprietary slicing platform designed to handle complex fluid dynamics and live material mixing, enabling high-speed, continuous printing without sacrificing geometric precision.

VEER also supports intelligent path planning and non-linear layer thickness control, resulting in smoother surfaces and eliminating traditional layer-based textures.

Real-World Adoption: From BMW to Haute Couture

Levity is already being piloted with industrial leaders like BMW, enabling tool-free, low-volume production of complex parts. In healthcare, it enables rapid fabrication of customized prosthetics and air-inflatable medical structures. In design and fashion, Levity made headlines by helping Coperni create a printed hollow handbag showcased at Paris Fashion Week.

RLP is pursuing a hybrid business model, offering:

- Service bureau printing

- Full equipment sales

- Application-specific development support

Specifications and Market Launch Plan

Feature | Details |

External Dimensions | 129 × 117 × 223 cm |

Build Volume | 50 × 50 × 50 cm |

Compatible Materials | Silicone, Polyurethane, Photocurable Elastomers |

Support Structures | Not required – prints in suspension |

Post-Processing | Water rinse only |

Commercial Release | Scheduled for 2026 |

Go-to-Market Plan | Hybrid sales & services; global rollout underway |

From Lab to Factory—Levity is Reinventing Additive Manufacturing

With Levit, Rapid Liquid Print is redefining how we understand structure, material, process, and sustainability in 3D printing. From eliminating support structures to enabling intelligent multi-material paths, Levity marks a new era in industrial liquid printing.

For RLP, this isn’t just a technological leap—it’s a “levity revolution” for the future of manufacturing.