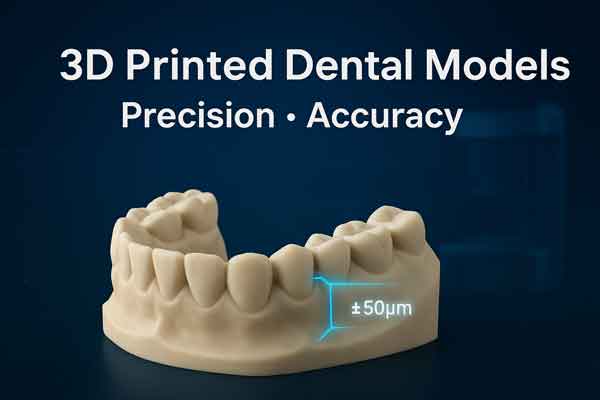

Dental models are the cornerstone of patient care, serving as a critical visualization and fabrication tool for everything from implant planning and restoration fabrication (like crowns and bridges) to the demonstration of complex orthodontic treatment pathways. The quality and reliability of these models directly impact treatment success. As digital dentistry continues its rapid ascent, 3D printed dental models are increasingly becoming the method of choice for dental clinics and laboratories, primarily due to their superior precision and accuracy.

Why Precision and Accuracy Are Non-Negotiable in Dental Modeling

While often used interchangeably, precision and accuracy have distinct and vital meanings in dentistry.

- Precision (Repeatability): Refers to the consistency of results when printing the same model multiple times. High precision means minimal variation across a batch of models.

- Accuracy (Trueness): Measures how closely the printed model matches the patient’s actual oral data, which is captured via intraoral scanners or CBCT. High accuracy means a model is a true-to-life representation.

For applications like dental implant models, a high degree of both is paramount. A microscopic error in model accuracy can lead to a significant positional error for the implant fixture in the patient’s mouth. Similarly, dental study models used for aligner staging must perfectly represent the teeth’s morphology to ensure the appliance fits correctly. The clinical standard is demanding, with the American Dental Association (ADA) accepting a maximum restorative margin gap of 120 μm. Modern 3D printing is engineered to meet, and often exceed, this standard.

The Digital Workflow: Manufacturing 3D Printed Dental Models

The creation of a 3D printed model follows a streamlined digital workflow:

- Data Acquisition: The process begins with capturing the patient’s oral anatomy using an intraoral scanner or CBCT.

- Digital Modeling: The data is converted into a digital 3D design (STL file).

- 3D Printing: The photopolymer resin is solidified layer-by-layer by a high-resolution 3D printer.

- Post-Processing: The model is cleaned and subjected to a final light cure to achieve its ultimate mechanical properties and dimensional stability.

The core strength of the resin-based printing process is its ability to print with high-resolution layer thicknesses (often 50 to 100 μm), and the speed and consistency of the photocuring reaction, leading to high-fidelity dental modelling.

Factors Governing Model Quality: From Data to Post-Cure

Achieving a high-quality, accurate, and precise 3D printing dental model is a result of meticulous control across the entire workflow. Several critical factors influence the final outcome:

- 3D Printer Technology: Resolution (X/Y axis precision) and light source stability directly determine the smallest detail the printer can reproduce. For optimal results, pairing the resin with a high-quality printer is essential.

- Resin Material Performance: The chemical properties of the resin, such as its polymerization shrinkage and viscosity, are key. High-performance resins like Ifun’s 3160 Dental Model Resin are specifically formulated with a low shrinkage rate (less than 0.5%) to ensure the cured model retains the digital design’s dimensional accuracy.

- Post-Processing Protocol: The consistency of cleaning and secondary curing is vital. Proper post-curing enhances the model’s strength and final dimensional stability, while improper post-processing can introduce or amplify minor errors.

- Source Data Quality: The initial accuracy of the intraoral scan or CBCT data directly sets the upper limit for model accuracy. Garbage in, garbage out—even the best printer and resin cannot correct flawed source data.

Each step introduces the potential for a minor error, emphasizing the need for a reliable material and a standardized process.

3D Printing vs. Traditional Dental Models: A Clear Superiority

The contrast between modern 3D printing and traditional model fabrication is striking:

Traditional Methods (Plaster Models)

| Advantages | Disadvantages |

| Historically trusted, low-cost materials (gypsum). | Fragile (easily chipped/broken). |

| Requires time-consuming manual trimming with tools like a dental model trimmer. | |

| High potential for human error during impression taking and plaster pouring. | |

| Difficult to store digitally and reproduce precisely. |

3D Printing Methods

| Advantages | Features |

| Superior Precision and Repeatability: Modern research shows high-quality resin models typically have a Root Mean Square (RMS) error of 129 to 143 μm, significantly better than the traditional method’s error of around 177 μm. | High Durability: Resins like Ifun’s 3160 offer a surface hardness (>82 Shore D) comparable to or better than gypsum, resisting breakage even during repeated insertion and removal of implant analogs. |

| Workflow Efficiency: Models are stored digitally and can be printed on demand, offering high throughput for dental models. | Specific Application Advantages: Ifun’s 3160 offers a heat deflection temperature of up to 120∘C, ensuring dental model teeth do not deform during the thermoforming of clear aligners. |

The ability of 3D printing to precisely reproduce complex geometries and ensure consistent quality has positioned it as a reliable alternative, often outperforming the traditional gold standard.

Clinical and Laboratory Value

The adoption of photopolymer 3D printed dental models delivers significant benefits to both clinical and lab settings:

For the Clinic: Enhanced Patient Care

- Rapid Chairside Models: Quick in-house printing of dental study models can drastically reduce patient waiting times for aligners, retainers, or temporary restorations.

- Improved Communication: Highly detailed, matte-finish models (like those from Ifun’s 3160 Resin) make it easier for dentists to mark and visualize treatment details, enhancing patient understanding and acceptance.

- Pinpoint Implant Accuracy: The ultra-high assembly accuracy of Ifun’s 3160 (±20 μm) ensures flawless guide positioning for surgical procedures, providing confidence in complex dental implant models cases.

For the Laboratory: Efficiency and Quality

- High-Volume, Consistent Output: Laboratories can reliably batch-produce dental models with a dimensional tolerance controlled within 0.08 mm, ensuring consistent quality across high-volume daily use.

- Durable Working Models: The high flexural strength (>60 MPa) of resins allows models to withstand repeated handling during trial fittings and adjustments of crowns and bridges without damage.

- Long-Term Reliability: Excellent low creep properties ensure the model remains stable over time, making it suitable for long-term storage and future follow-up connections.

The Future of Dental Models Is Digital

3D printed dental models are not just a technological curiosity; they are now a reliable, high-precision tool that meets and often surpasses the demanding accuracy requirements of modern clinical and laboratory dentistry. The consistent quality, durability, and high-fidelity detail provided by dedicated materials like Ifun’s 3160 Dental Model Resin offer significant workflow advantages over traditional plaster casting.

The future of dental models is undoubtedly digital. We expect further advancements in material stability, faster printing technology, and the continued integration of AI-driven optimization, making the complete replacement of traditional gypsum models an inevitability.

Ready to experience the next level of precision in your practice? We encourage you to explore the capabilities of high-precision photopolymer dental model resins and see how they can transform the accuracy and efficiency of your dental workflow.