Resin printing post-processing is complex with multiple steps and tool/process demands. Surface quality is ensured by controlling both the printing and post-processing.

The complexity of the post-processing process after resin printing

The post – processing process after resin printing has a certain degree of complexity.

Multiple steps and interrelated

- First of all, after the photocuring 3D printing of resin is completed, the basic post – processing process includes removing the part, removing the support, cleaning the model, post – curing, sanding, splicing and repairing, and painting. Removing the part requires careful operation. For example, after the workbench rises above the liquid level, it needs to stay for 5 – 10 minutes to dry the excess resin before the subsequent action of removing it from the platform. If the molded part is too soft, it should be removed together with the lifting platform plate for post – curing treatment.

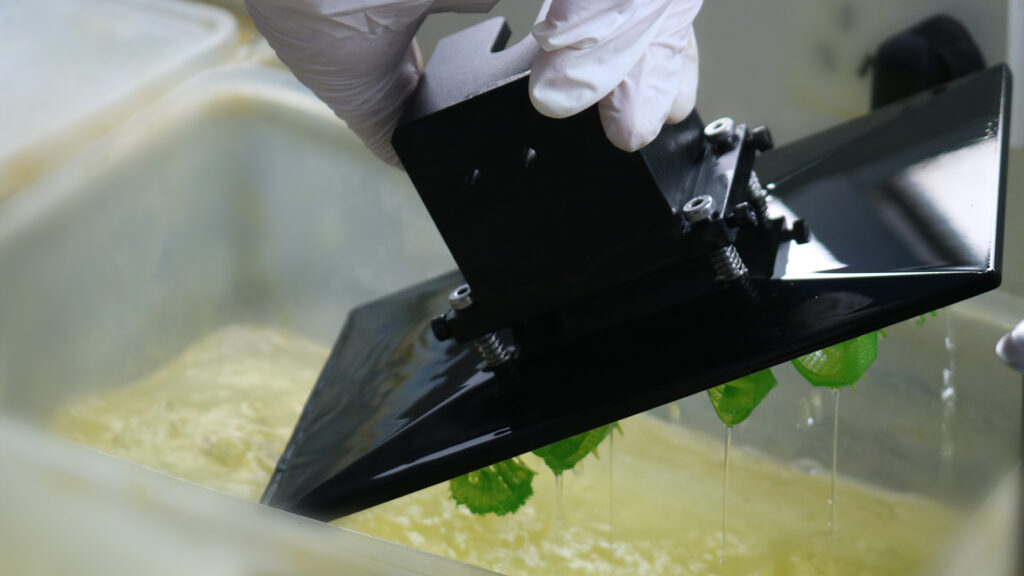

- Cleaning the model is not a simple step and requires multiple operations. Before taking out the model, the prototype and the workbench may need to be placed sideways to dry, then put into a cleaning solution such as toluene or alcohol, stirred for cleaning and remove air bubbles. After about 45 minutes, the workbench needs to be cleaned in a water reservoir for about 5 minutes. For the uncured resin that may remain inside the molded part, a liquid outlet hole should be preset when designing the model or drilled after molding to drain it. Otherwise, the subsequent curing shrinkage of the residual resin will cause deformation. After that, the surface of the prototype part needs to be cleaned again, which requires further treatment according to the nature of the solvent, such as washing off the water-soluble solvent with cold water and then drying it, or removing the liquid resin on the surface with a cotton ball dipped in an organic solvent.

- Support removal needs to be done carefully. For relatively brittle resin materials, removing the support after post – curing is likely to damage the product. Therefore, it is recommended to remove it before post – curing. And if processes such as electroplating or painting are carried out after removing the support, the support marks on the surface need to be further sanded and other treatments.

- Post-curing involves that if the strength of the prototype part formed by laser irradiation is not enough, it needs to be cured again by means of ultraviolet lamp irradiation or heating, and the requirements of uniform curing and appropriate curing time need to be met to avoid stress concentration and other situations.

Many requirements for tools and processes

- Each operation requires specific tools to assist. For example, cleaning can use ultrasonic cleaning tanks, basket flushing (soaking in an IPA bath), etc. Among them, ultrasonic cleaning is highly professional and has good effects, but it is expensive; basket flushing is simple and fast but the effect is slightly inferior. For sanding, if the requirements for processes such as painting or electroplating are relatively high, it is necessary to use various sandpaper grits from coarse to fine for multiple repeated sanding, which has certain requirements for operating techniques and experience.

- In the painting process, in addition to selecting colors according to the requirements of the client (involving different situations of hand – shaking spray painting or spraying with compressed air through a spray gun), if it is high – specification painting, it also involves accurately adjusting colors according to the color card. At the same time, under different splicing and repair requirements, slow – drying glue should be used to repair large gaps or missing parts, while small model splicing gaps or small missing parts are suitable for repair with quick – drying glue and can be used in conjunction with an accelerator to speed up the curing time, which has high requirements for users to accurately judge the use scenario and process.

Methods to ensure surface quality after resin printing

Control of the printing process

- Rationality of model design: In the model design stage, the material characteristics in the resin printing process and the requirements of the printing technology should be considered. For example, for parts that are prone to deformation, the structure should be optimized to ensure the stability of the model structure. According to the strength and flexibility of the resin material, the shape and proportion of the model should be reasonably set to prevent deformation due to uneven structural stress during the printing process, thus affecting the surface quality.

- Optimization of printing parameters: Printing speed is a key parameter. Too fast a printing speed may cause the resin material to heat up too quickly, leading to deformation. Therefore, a suitable printing speed should be set according to the performance of the resin material and the characteristics of the printer. Exposure time is also very important. Too short an exposure time will make the resin curing incomplete, affecting the surface hardness and smoothness. Too long an exposure time may cause the bottom of the model to warp or be difficult to remove from the platform. The exposure time needs to be accurately adjusted according to the resin type and model size.

Ensure in the post-processing process

- Thoroughly clean the surface: The cleaning process directly affects the surface quality. During the initial cleaning, the uncured resin on the surface should be removed as thoroughly as possible. If ultrasonic cleaning is used, although the cost is high, it can effectively remove the fine layer of uncured resin on the model and obtain a smooth surface. If the method of basket and flushing (soaking and flushing in IPA) is used, multiple operations may be required to ensure cleanliness, so as to ensure the smooth progress of subsequent processes such as curing and sanding without affecting the surface quality. At the same time, the uncured resin remaining inside the molded part should also be properly handled to prevent surface deformation caused by resin shrinkage during the post-curing process.

- Reasonable post – curing operation: Post – curing is crucial for adjusting the material properties of the resin. Insufficient post – curing may lead to problems such as insufficient surface hardness and poor scratch resistance. For functional resins, post – curing usually needs to be carried out by means of ultraviolet lamp irradiation or heat curing. In the operation, a post – curing device with a suitable power should be used. For example, when using a 600W full-band ultraviolet lamp, the post-curing time for each side should be controlled within 10 – 30 seconds, and each side should be evenly exposed to ultraviolet light, which can avoid cracking and deformation problems caused by stress concentration and enable the model to obtain better surface quality and overall performance.

- Fine sanding skills: Sanding can significantly improve the surface quality. First, select the appropriate sandpaper. For models without special requirements, only the support surface needs to be sanded. If a higher surface finish is required (such as painting or electroplating), the sandpaper should be gradually changed from coarse to fine for sanding. During the sanding process, finger coats should be worn and the force should be kept uniform to avoid unnecessary scratches or over-sanding on the model surface. Especially for parts of the model with rich details or high precision requirements, more careful operation is needed to ensure that the overall appearance and the quality of the details of the model are not damaged while improving the surface smoothness.