Discover essential tips and techniques for maintaining resin 3D printers. Learn daily upkeep, troubleshooting common issues, and extending the lifespan of your 3D printer. From nozzle cleaning to resin management, this guide has you covered for optimal performance.

Daily maintenance methods for resin 3D printers

Daily maintenance of resin 3D printers is key to ensuring their stable operation and print quality.

- Clean printing parts

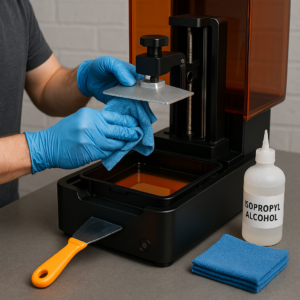

- Nozzle and construction platform: During the printing process, resin may remain on the nozzle or construction platform. For the nozzle, if there is residual resin solidification blockage, you can use a special cleaning solution to soak the nozzle tip, soften the resin, and gently clean it with a soft brush, paying attention not to damage the nozzle structure. Resin residue on the construction platform will affect the flatness of the bottom of the model. After each printing is completed, carefully scrape off the resin on the platform with a scraper, and then wipe it clean with an alcohol cotton ball to ensure that the platform is smooth and residue-free.

- Resin tank: The resin tank is an important component of the resin 3D printer, where the resin is cured and formed. After use, there may be residual uncured resin and impurities generated during the curing process in the tank. It is necessary to regularly pour out the resin in the tank and use a clean cloth or a special wiping tool to remove the residual resin and impurities in the tank. If the resin tank is scratched or damaged, it may affect the printing quality and needs to be replaced in time.

- Check moving parts

- Slide rail and guide rail: They are the key to ensuring accurate movement of the printing head or construction platform. Regularly check whether there is dust or resin particles attached to the slide rail and guide rail. If there is, use a clean soft cloth dipped in a small amount of lubricant to gently wipe it, remove dirt, and lubricate it at the same time. Be careful not to use too much lubricant to avoid lubricant dripping into other components or resin tanks, contaminating the resin.

- Belt and chain (if any): Some resin 3D printers use belt or chain drive to drive the nozzle or platform movement. Check if the belt is loose. If the belt is loose, it will affect the motion accuracy and cause the printing layer to be misplaced. For the chain, check for oil shortage, rust or wear. If the belt is loose, adjust the belt tensioning device to restore its appropriate tightness; if the chain is short of oil and rusted, use special chain lubricating oil for maintenance.

- Resin management

- Resin stirring: If the resin is left standing for a long time, there may be precipitation or uneven composition, which affects the printing effect. Before each printing, use a clean stirring rod to slowly and evenly stir the resin, so that the various components of the resin are fully mixed.

- Resin filtration (optional): If more impurities are found in the resin, a filter can be used to filter the resin, remove the impurities, and then pour it into the resin tank for printing. However, it is important to choose a filter with an appropriate mesh size to avoid the filter being too thin and affecting the normal flow of the resin.

- Environmental maintenance

- Temperature Control: Resin 3D printers have certain requirements for ambient temperature, and the suitable working temperature is generally between 20-30 ℃. If the temperature is too high, it may cause the resin to solidify too quickly and clog in the nozzle or pipeline; if the temperature is too low, it may make the resin flow worse and affect printing accuracy. If the ambient temperature cannot be maintained within this range, consider using air conditioning or heating equipment to adjust the temperature.

- Humidity control: The environmental humidity should be maintained at a relatively stable level. Excessive humidity may cause the resin to absorb moisture, affect its curing performance, and easily breed microorganisms such as mold inside the printer. It is more appropriate to maintain the environmental humidity at 40% -60%, and a dehumidifier or humidifier can be used to adjust the humidity.

- Clean the work area: Keep the work area around the printer clean to prevent dust, debris and other debris from entering the printer or falling into the resin tank. Regularly clean the work area and wipe the printer housing.

Maintenance tips and precautions for resin 3D printers

Resin 3D Printer Maintenance Tips

- Regular deep cleaning

- Frequency: Depending on the frequency of use, it is recommended to perform a deep cleaning every 1-2 weeks. Deep cleaning not only involves surface wiping, but also cleaning internal components.

- Method: For the inside of the printer, open the shell (if allowed) and use a compressed air tank to blow off the dust and resin particles inside. For some difficult-to-blow dirt, a small brush can be used to gently brush it off, and then the dirt can be sucked away with a vacuum cleaner. For external components such as the shell and control panel, a slightly damp soft cloth can be used to wipe them off, and then dried with a dry cloth to prevent moisture from entering the inside of the printer.

- Calibration and testing

- Printing Platform Calibration: The flatness of the printing platform is crucial for print quality. Regularly check whether the platform is level with a level or the calibration tool provided by the printer. If the platform is not level, it may cause poor adhesion between the bottom of the model and the platform, and even print failure. When adjusting the platform level, it is generally achieved by adjusting the screws below the platform.

- Motion axis accuracy detection: Use professional measuring tools or the built-in detection program of the printer to check the accuracy of the nozzle or platform motion axis. If any deviation is found in the motion axis, it can be corrected by adjusting the motor parameters or fine-tuning the mechanical components.

- Light source intensity detection (for photocurable printers): The light source intensity of photocurable resin 3D printers will decay with increasing use time. Regularly use a light intensity meter to detect the light source intensity. If the intensity is found to be lower than the normal level, it may be necessary to replace the light source or repair the light source.

- Software maintenance

- Firmware Updates: Printer manufacturers will continuously release new firmware versions to fix known vulnerabilities, improve printer performance and compatibility. Regularly check the official website of the printer manufacturer to see if there are new firmware versions available for updates. When updating firmware, strictly follow the update guidelines provided by the manufacturer to avoid errors during the update process.

- Slicing software update and optimization: Slicing software is a key tool for converting 3D models into printer-recognizable instructions. The algorithm of slicing software is constantly improving, which can improve the efficiency and printing quality of slicing. Timely update the slicing software to the latest version, and adjust the slicing parameters according to different models and resin types, such as layer thickness, exposure time, support structure, etc.

Notes

- Safe operation

- Resin protection: Resin has certain chemical properties and may cause irritation to the skin and eyes. When operating the resin, wear protective equipment such as gloves and goggles. If the resin accidentally comes into contact with the skin, immediately rinse with plenty of water; if it comes into contact with the eyes, seek medical attention as soon as possible.

- Electrical safety: When maintaining or operating the printer, make sure the printer is powered off. Avoid operating the printer in a humid environment to prevent electric shock accidents.

- Avoid overuse

- Continuous printing duration: Although resin 3D printers can work continuously, long-term continuous printing may cause problems such as overheating of printer parts and insufficient resin supply. It is recommended to control the continuous printing duration within a reasonable range, such as no more than 24 hours. If a large model needs to be printed for a long time, it can be printed in stages, leaving appropriate rest time for the printer in between.

- Consideration of component lifespan: Each component of the printer has its own lifespan, and excessive use can accelerate component wear. For example, frequent use of the nozzle may accelerate its wear and affect printing accuracy. Based on the lifespan of the components and the frequency of printer use, arrange printing tasks reasonably, and regularly inspect and replace the components.

How to extend the lifespan of resin 3D printers

Correct usage habits

- Follow the operation manual: The operation manual is a guide for using the printer, which includes important information such as the correct operation method and parameter setting range of the printer. Strictly follow the operation manual to start, print, shut down and other operations of the printer to avoid damage to the printer due to incorrect operations.

- Reasonably set printing parameters

- Layer thickness setting: Layer thickness is an important parameter that affects printing accuracy and printing time. Thinner layer thickness can achieve higher printing accuracy, but printing time will increase accordingly; thicker layer thickness can print faster, but accuracy will decrease. According to the needs of the printing model, the layer thickness parameter should be reasonably selected. Generally speaking, for fine models, a layer thickness of 0.05-0.1mm can be selected; for models that do not require high accuracy, a layer thickness of 0.1-0.2mm.

- Exposure time: In a photocurable resin 3D printer, the exposure time determines the degree of resin curing. Exposure time that is too long may cause the resin to over-cure, making the model brittle, and may generate stress inside the model, causing deformation; exposure time that is too short may cause the resin to not fully cure. Depending on the type of resin and the performance of the printer, the optimal value can be determined by testing different exposure times.

- Support structure settings: Reasonable support structures can ensure the stability of the model during the printing process, but excessive support structures will increase printing time and post-processing difficulty. In slicing software, appropriate support structure types and parameters should be set according to the shape and structure of the model to minimize unnecessary support.

High-quality materials and accessories

- Choose high-quality resin: High-quality resin has better fluidity, curing performance, and stability. Low-quality resin may contain more impurities, which can easily clog the nozzle or affect the curing effect, thereby affecting the service life of the printer. Choose well-known brands and certified resin products, and choose the appropriate resin type according to different printing needs (such as hardness, flexibility, transparency, etc.).

- Use genuine accessories: If a part of the printer is damaged and needs to be replaced, try to use genuine accessories. Genuine accessories are guaranteed in terms of dimensional accuracy, material quality, and compatibility, which can better adapt to the printer and avoid further damage caused by using inferior accessories.

Regular maintenance and upkeep

- Establish a maintenance plan: Develop a detailed maintenance plan based on the frequency of use and environmental conditions of the printer. For example, for printers used every day, perform a basic cleaning and inspection once a week; perform a deep cleaning and calibration once a month; and perform performance testing on key components (such as printheads, light sources, etc.) every quarter.

- Timely handling of minor issues: During the use of the printer, if any minor issues are found, such as slight noise or a slight decrease in print quality, they should be checked and dealt with in a timely manner. If minor issues are not resolved in a timely manner, they may gradually evolve into major issues, causing more serious damage to the printer.

Common malfunctions and repairs of resin 3D printers

Print failure type fault

- Model not fully printed

- The reasons: may be insufficient resin supply, such as insufficient resin in the resin tank or blocked resin pipes; improper printing parameter settings, such as thin layer thickness and short exposure time, resulting in incomplete resin curing; unreasonable support structure settings, resulting in partial collapse of the model during printing.

- Maintenance method: Check the amount of resin in the resin tank, supplement enough resin; clean the resin pipeline to ensure smooth supply of resin. Adjust the printing parameters, reset the layer thickness and exposure time according to the resin type and model requirements. Optimize the support structure, re-slice and print.

- Model surface roughness

- Reasons: The nozzle is blocked or there is residual resin, resulting in uneven resin extrusion; the layer thickness is set too thick, making the surface of the model not smooth enough; resin quality problems, such as impurities or particles in the resin.

- Maintenance method: Clean the nozzle, remove blockages and residual resin. Adjust the layer thickness parameter, appropriately reduce the layer thickness to improve surface smoothness. Replace the resin and use high-quality, impurity-free resin for printing.

Mechanical motion failure

- Sprinkler or platform motion card

- Reasons: Dirt and resin particles on the slide or guide rail increase friction resistance; belt relaxation or chain oil shortage rust affects transmission effect; motor failure, such as insufficient motor power or internal damage to the motor.

- Maintenance method: Clean the slide and guide rails, apply appropriate amount of lubricant. Adjust the belt tension or lubricate the chain. Check the motor and replace it if there is a fault.

- Inaccurate positioning of motion axis

- Reasons: It may be a malfunction of the limit switch of the motion shaft, resulting in inaccurate limit setting; incorrect setting of motor driver parameters, affecting the positioning accuracy of the motion shaft; wear of mechanical components, such as wire rod wear, resulting in inaccurate platform lifting position.

- Repair method: Check the limit switch and replace it if damaged. Reset the motor driver parameters and adjust them according to the printer’s technical manual. Replace or repair worn mechanical parts.

Resin-related failure

- Incomplete curing of resin

- Reasons: insufficient exposure time, insufficient light source intensity, or expired resin.

- Maintenance method: Increase exposure time and determine the appropriate exposure time through testing. Check the intensity of the light source and replace it if the intensity is insufficient. Check the valid period of the resin and replace the expired resin.

- Resin blocking pipes or nozzles

- Reason: the resin remains in the pipeline or nozzle for too long, causing blockage after solidification; impurities in the resin accumulate in the pipeline or nozzle.

- Maintenance method: For minor blockages, soak the pipeline or nozzle in cleaning solution, soften the resin, and blow through with compressed air. For severe blockages, it may be necessary to disassemble the nozzle or pipeline for cleaning, or directly replace the blocked parts.

Regular maintenance points for resin 3D printers

Short-term regular maintenance (daily/weekly)

- After printing, clean up: After daily printing, perform a simple cleaning of the printer. This includes cleaning the resin residue on the build platform, wiping the nozzle (if exposed), checking the remaining amount of resin in the resin tank, and stirring the resin (if necessary).

- Moving parts inspection: Check the moving parts of the printer every week, such as slides, guides, belts, etc. Check whether the slides and guides are clean, clean and lubricate them in time if there is dirt; check the tightness of the belt, and adjust it if there is any looseness.

- Resin tank maintenance: Check the resin tank every week to see if there is any resin leakage or contamination in the tank. If impurities are found in the resin, a filter can be used to filter or replace the resin.

Mid-term regular maintenance (monthly/quarterly)

- Deep cleaning: Perform a deep cleaning once a month, including cleaning the inside of the printer. Open the printer housing (if allowed), use tools such as compressed air and a small brush to remove dust and dirt inside. At the same time, thoroughly wipe the outside of the printer to keep the appearance clean.

- Component calibration: Calibrate the key components of the printer monthly or quarterly, such as the levelness calibration of the printing platform and the accuracy calibration of the motion axis. Calibration can be done using the calibration tool provided by the printer or professional measurement tools.

- Resin management: Check the quality and performance of the resin every month to see if there are any discoloration, thickening and other phenomena. If the performance of the resin changes, it may be necessary to replace the resin. At the same time, clean the storage container of the resin to ensure that the container is clean and well sealed.

Regular long-term maintenance (annually)

- Replacement or repair of key components: Inspect and evaluate some key components of the printer every year, such as the nozzle, light source (for light-cured printers), motor, etc. If significant wear or performance degradation is found in the components, consider replacing or repairing them.

- Overall Performance Test: The overall performance of the printer is tested once a year, including tests on printing accuracy, motion speed, resin curing effect, etc. Based on the test results, the printer is adjusted and optimized to ensure its performance is at its best.