SLA/DLP/LCD resin printing technology, known for its high precision and detailed output, is increasingly integral to various manufacturing sectors. However, the printing process is highly sensitive to environmental conditions, with ambient temperature and humidity being critical factors affecting print quality and success rates. Precisely controlling these parameters is crucial for ensuring optimal resin curing, the mechanical strength of printed parts, and surface finish. This article delves into the mechanisms by which temperature and humidity influence resin printing, offering control strategies to help users optimize their printing environment and achieve superior results.

I. Influence of Ambient Temperature on Resin Prints and Control Techniques

Temperature primarily affects the viscosity and curing reaction speed of the resin.

Positive Correlation Between Curing Speed and Temperature

- Accelerated Molecular Movement and Reaction: An increase in temperature (typically within the 20-35°C range) significantly boosts resin molecular activity, speeding up the photoinitiator’s reaction efficiency and thus shortening curing times. For instance, standard resin might take several hours to cure at 25°C, but in a cold environment of 5°C, the curing time could extend beyond 24 hours.

- Critical Temperature Limits: While warming aids curing, higher temperatures aren’t always better. When the ambient resin printing temperature exceeds 30°C, the polymerization reaction within the resin can lead to exothermic runaway, causing a sharp increase in internal stress that can result in print warping or cracking. Conversely, at low temperatures (below 15°C), resin viscosity significantly increases, and its fluidity decreases. This can hinder proper resin flow back and leveling between layers during printing, leading to poor layer adhesion or even print failures.

Temperature Control Strategies

Industrial Solutions:

- Constant Temperature Systems: High-end industrial 3D printers, such as Stratasys machines, often feature built-in precision temperature control modules that maintain the printing chamber environment at an ideal 22-28°C.

- Layer-by-Layer Curing Control: For thick-walled or large-volume prints, techniques like phased printing or optimized slicing parameters can be used to prevent excessive heat accumulation during a single curing cycle, reducing the risk of exothermic runaway.

Low-Cost Solutions:

- Heating Pads: Attaching heating pads to the bottom of the resin vat is an economical way to maintain the resin temperature at an optimal 20-25°C.

- Pre-heating Resin: In cold environments, pre-heating sealed resin bottles by soaking them in 30°C warm water for about 10 minutes can reduce resin viscosity and improve initial printing performance.

- Printer Enclosures: Using an insulated enclosure or a simple heated box around your printer helps stabilize the internal resin print temperature.

II. Influence of Humidity on Resin Prints and Control Techniques

Humidity primarily affects the resin’s moisture absorption and curing quality.

Viscosity and Curing Quality’s Humidity Dependence

Negative Effects of High Humidity (above 80% RH):

- Moisture Penetration Forming Weak Interface Layers: Resin is somewhat hygroscopic. In high humidity, atmospheric moisture can penetrate the resin, creating “weak interface layers” between print layers. This significantly reduces inter-layer adhesion strength, making prints prone to delamination or breakage.

- Accelerated Resin Viscosity Growth: The presence of moisture can accelerate the resin’s polymerization reaction, causing its viscosity to increase too rapidly. This shortens the resin’s usable working time (i.e., the “viscosity inflection point” moves up by 50%), increasing the risk of print failure.

Risks of Low Humidity (below 30% RH):

- Extremely low humidity, while reducing moisture interference, can cause the resin to cure too quickly, increasing internal stress and potentially leading to print delamination.

Humidity Control Strategies

Industrial Standards: Industrial-grade resin printing environments typically control relative humidity to an ideal range of 30-60% RH, achieved through professional dehumidifiers or constant humidity equipment.

Small Studio Solutions:

- Sealed Printing Chambers: Using a well-sealed printing chamber with desiccant materials (like silica gel) inside can effectively lower local humidity.

- Environmental Monitoring: Deploying sensors such as DHT11 connected to an Arduino system or similar open-source hardware allows for real-time monitoring of environmental temperature and humidity, alerting users when thresholds are exceeded for timely intervention.

- Dehumidifiers: In highly humid areas, using a household dehumidifier is an effective way to control room humidity.

III. Synergistic Effects of Temperature and Humidity & Integrated Control

Temperature and humidity do not act independently; they exhibit complex interactive influences.

Cases of Interactive Influence

- High Temperature and High Humidity: This combination presents the most challenging resin printing environment. High temperature accelerates resin reaction, while high humidity introduces moisture interference. For example, in high temperature and high humidity conditions, the resin’s “viscosity inflection point” can shorten from 50 hours to 25 hours, and the risk of exothermic runaway doubles, greatly increasing print failure rates and quality defects.

- Low Temperature and Low Humidity: While low temperature increases viscosity and slows curing, and low humidity might accelerate curing and cause delamination, the combination of these conditions can lead to both incomplete curing and delamination risks, resulting in unstable print performance.

Recommended “Golden Zone”

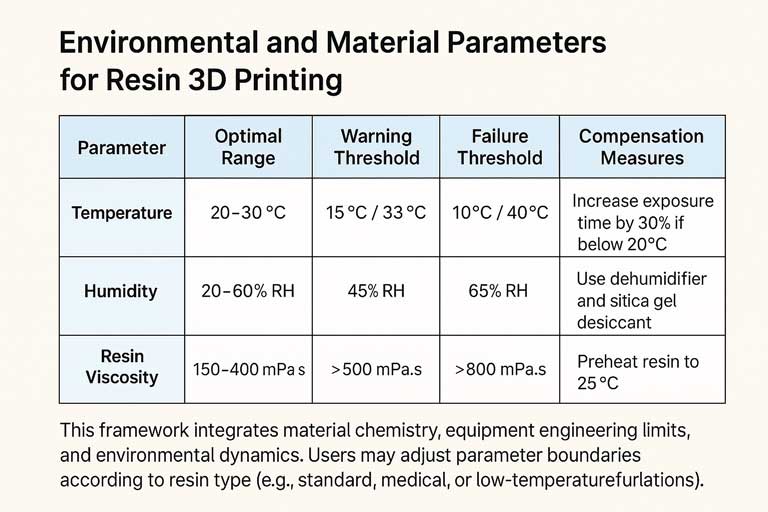

Based on extensive practical data, here are the ideal “golden zone” and critical thresholds for resin printing temperature and humidity:

IV. Advanced Scenarios and Solutions

For specific resin types and more complex printing requirements, more specialized environmental control measures can be adopted.

Resin-specific Sensitivities

- Differential Response of High vs. Low Viscosity Resins: High-viscosity resins are more sensitive to low temperatures, as their inherently poor flow is further exacerbated, affecting layer filling and curing. Low-viscosity resins, on the other hand, are more prone to excessive flow and detail loss at high temperatures.

- Increased Sensitivity of Certain Resins: Resins like biocompatible or wax-based types are often more sensitive. Medical or transparent resins typically require higher curing temperatures (e.g., 25-30°C) to ensure optimal performance and optical clarity; pairing them with auxiliary heating equipment like infrared heating lamps is recommended. Wax-based resins are particularly sensitive to temperature fluctuations and require a more stable environment to prevent deformation.

Smart Environmental Systems:

- LoRa Networking: Deploying a distributed temperature and humidity sensor network based on LoRa technology allows for real-time monitoring of multiple printing areas. Sensor data can link with air conditioners, dehumidifiers, and other equipment via gateways to enable automated control of the resin printing environment.

- Open-Source Hardware: Utilizing ESP32 microcontrollers with platforms like Home Assistant, users can build low-cost automated temperature and humidity monitoring and control systems, enabling remote monitoring and smart linkages.

Post-Processing Optimization:

- Post-Processing in High-Humidity Environments: For parts printed in high-humidity conditions, even if the print seems successful, internal “weak interface layers” may still exist. An additional baking treatment after curing, such as baking at 60°C for 2 hours, is recommended to eliminate these potential weaknesses and enhance the print’s mechanical properties and stability.

Conclusion

Controlling temperature and humidity in resin printing is essentially a process of balancing molecular dynamics with material rheology. In industrial settings, this relies on precise environmental control equipment (like Stratasys’s temperature control modules). For home users or small studios, low-cost solutions such as sensor networks and physical adjustments (e.g., resin pre-heating, sealed printing chambers) can optimize the environment. Continuous monitoring and dynamic adjustment are core to ensuring print accuracy and success rates. It is recommended that users verify environmental parameters before each print job and prioritize resin types with broader temperature and humidity adaptability (e.g., some brands like Liqcreate Rigid Pro offer wider environmental compatibility). By meticulously managing environmental factors, users can significantly improve resin print temperature consistency, success rates, and the final quality of their printed parts.