The ultimate in white wax casting resin shrinkage: IF900D

The ultimate in white wax casting resin shrinkage: IF900D,Revolutionizing Jewelry Casting with IFUN’s Innovative 3D Printing Resin

Introduction:

In the ever-evolving world of jewelry casting, the demand for precision and quality has never been higher. Recently, the discovery of a common issue – the shrinkage factor in white wax resin – sparked a challenge within the industry. Acknowledging this problem, IFUN took the initiative to address it, ultimately paving the way for a groundbreaking solution.

The Shrinkage Conundrum:

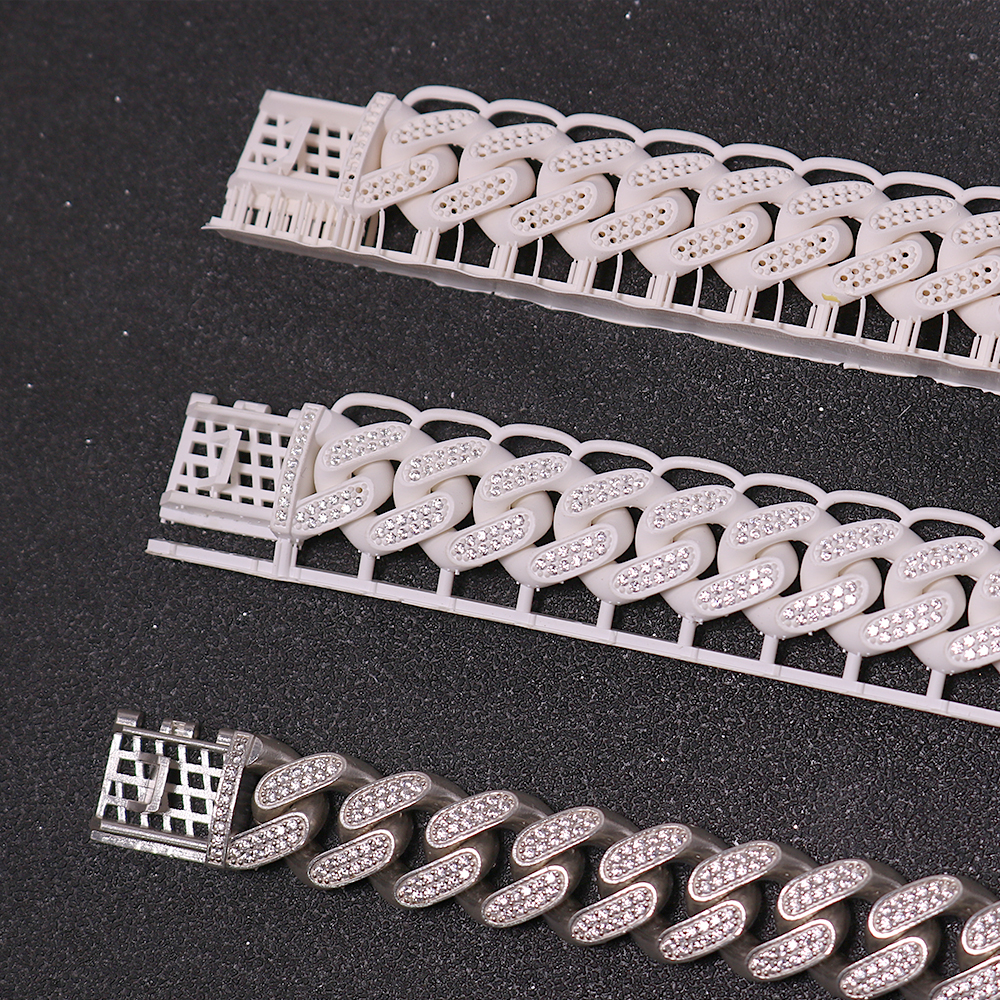

White wax resin, renowned for its ease of casting and residue-free burning, faced a significant setback – shrinkage. This flaw became a focal point when a jewelry factory shared insights, emphasizing that conquering the shrinkage rate of white wax could potentially crown a market leader. Responding to this call, IFUN’s research and development team embarked on an extensive journey, resulting in the creation of the revolutionary resin model, 900D.

Advantages of White Wax Resin:

IFUN’s 900D offers a myriad of advantages. It excels in printing minute details, produces a smooth surface without the need for polishing, facilitates easy support removal, and showcases exceptional casting results, making it an ideal choice for gold casting. The low shrinkage rate emerges as a key benefit, ensuring precise dimensions, stable storage without deformation, and accurate diamond embedding.

Technological Leap:

An additional breakthrough lies in the accessibility of IFUN’s white wax resin. While traditional options required expensive oxygen-permeable 3D printers, IFUN’s resin effortlessly achieves printing on LCD machines. This not only democratizes the technology but also significantly reduces costs for jewelers.

Complete Jewelry 3D Printing Ecosystem:

IFUN doesn’t stop at providing an innovative resin. The company offers a comprehensive suite of products tailored for jewelry 3D printing applications. This includes 3D printers (priced at a mere fraction of oxygen-permeable counterparts), high-power curing chambers, jewelry casting resins, and ultrasonic cleaning machines. Moreover, IFUN goes the extra mile by offering casting machines, zip machines, and more, providing a one-stop solution for all jewelry casting needs.

Conclusion:

IFUN’s dedication to solving the shrinkage issue in white wax resin has not only resulted in the game-changing 900D but has also opened doors for more accessible and cost-effective 3D printing solutions in the jewelry industry. As a professional and forward-thinking entity, IFUN stands as a beacon of innovation, offering a complete suite of services for all your jewelry casting requirements. Welcome to a new era of precision and efficiency with IFUN – your partner in revolutionizing jewelry casting.