Manifest Technologies—formerly known as Vitro3D, a spinout from the University of Colorado Boulder—has just launched its first evaluation kit for a new kind of 3D printing. Called Parallax Volumetric Additive Manufacturing (P-VAM), this tech was officially unveiled at RAPID + TCT 2025.

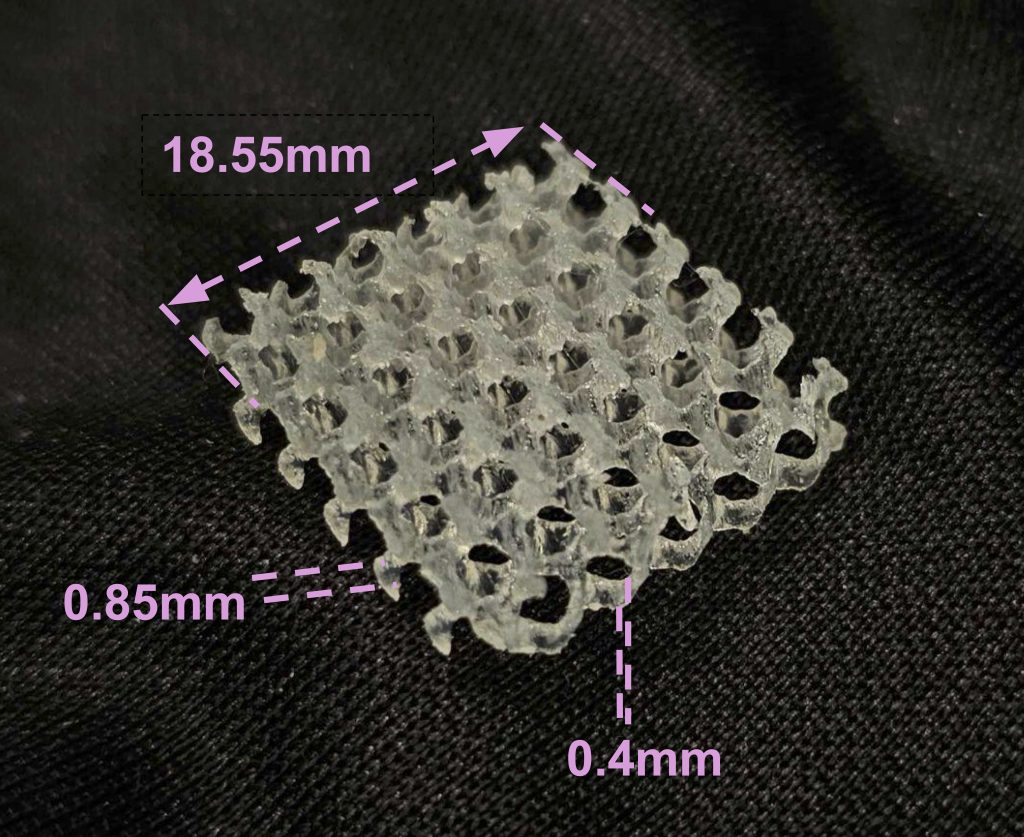

Instead of building objects layer by layer, P-VAM prints entire volumes at once. It uses a custom light engine and smart algorithms to cure photoreactive resin in three dimensions simultaneously. That means faster prints, no need for support structures, and a smaller setup that could fit right into your existing workflow.

You can catch live demos and check out sample prints at booth #3443. Manifest is actively looking for partners who want to explore volumetric printing for mass production and custom manufacturing.

“We started Manifest to totally rethink how additive manufacturing works,” said CEO and Co-Founder Camila Uzcategui. “Rather than printing in layers, our tech creates solid parts instantly with precisely controlled beams of light. As the older 3D printing methods slow down in innovation, we see P-VAM as a new path forward—and we’re inviting others to help us build that future.”

Compact, Modular, and Fast

P-VAM isn’t your typical 3D printer. It’s modular and compact, built to slide right into a high-speed production line like injection molding. By printing more complex parts all at once, it can even reduce or remove the need for extra assembly steps.

The evaluation kit includes:

- A precision printing unit with a high-powered laser and advanced optics

- A Zaber motion stage, custom PCB, wiring, and protective housing

- Pre-installed calibration, ready to go out of the box

- A starter supply of Arkema’s HT511 resin (optimized for this system)

It also comes with easy-to-use software. You can load standard 3D models, tweak designs, and simulate prints in real time. Everything runs in the cloud, so you’ll get updates and new features automatically.

And don’t worry about the learning curve—Manifest includes hands-on training and support to help teams test, customize, and fine-tune their systems for R&D or production.

The real kicker? Manifest claims P-VAM can print parts 10 to 100 times faster than traditional 3D printing. Plus, it works with high-viscosity transparent resins, opening up new applications where regular photopolymers fall short. You can also control resolution at different points of your print and scale up in the X-Y direction, depending on how detailed your part needs to be.

Volumetric Printing in the Bigger Picture

Volumetric 3D printing has been popping up more and more in cutting-edge research. For example:

- In 2024, BIO INX and Readily3D released a bioink called READYGEL INX, built for easy, plug-and-print use in volumetric bioprinting. It helps researchers create larger biological structures with minimal stress on cells.

- Back in 2022, scientists at Stanford and Harvard created a new approach using nanoparticles and light conversion. Their method cured resin only at very specific laser points, making support structures obsolete. It could even apply to things like solar tech and biomedical devices.