In April 2025, metal additive manufacturing (AM) specialist ADDiTEC made a big splash at RAPID+TCT by announcing a major upgrade to its technology lineup—the all-new FUSiON S system. This launch marks ADDiTEC’s official entry into Laser Powder Bed Fusion (LPBF), rounding out its portfolio alongside Laser Directed Energy Deposition (LDED) and Liquid Metal Jetting (LMJ). With this addition, ADDiTEC joins the ranks of a select few companies worldwide that offer all three major metal 3D printing technologies.

From Startup to Multi-Tech Innovator: The Journey of ADDiTEC

Based in Florida, ADDiTEC has rapidly grown its capabilities through smart partnerships and strategic acquisitions:

- 2019: Co-founded the MELTIO brand with Spain’s Sicnova 3D, focusing on metal AM platforms.

- 2023: Acquired Elem Additive Solutions, gaining access to ElemX, Xerox’s liquid metal 3D printing technology (now called LMJ).

- Launched AMDROiD and AMDROiD X, portable robotic metal AM systems for on-site production and repair, especially in defense and heavy industry.

- Introduced Hybrid 3, a multi-functional system combining LMJ, LDED, and CNC machining.

With the new LPBF-powered FUSiON S, ADDiTEC now offers a full suite of metal AM technologies—from ultra-precise parts to scalable production.

Meet FUSiON S: Precision Meets Safety

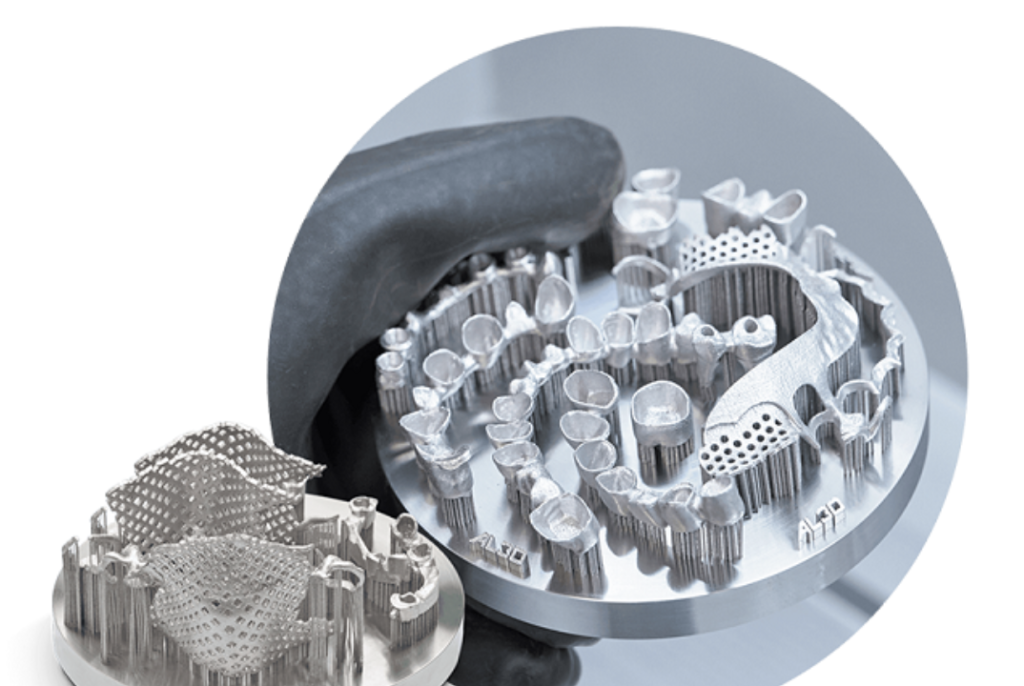

Developed with strategic partners, the FUSiON S blends proven LPBF technology with smart engineering. It offers industrial-grade performance in a compact 600 x 600 mm footprint and supports high-performance materials like cobalt-chrome, stainless steel, and titanium alloys.

A high-resolution laser spot ensures it can print complex geometries and fine features effortlessly.

To ensure user safety, FUSiON S uses a fully enclosed powder system, eliminating the need for operators to handle raw metal powder. It pairs seamlessly with the FUSiON Cabin unpacking station and an intelligent cartridge system—just plug in the cartridge, and you’re good to go. Leftover powder is automatically recovered and reused, saving costs and cutting waste.

Key Features & Use Cases

FUSiON S doesn’t just prioritize safety—it’s packed with performance features:

- High-speed scanning: Up to 5 meters/second

- Adjustable layer thickness: From 10 to 50 microns

- Smart UI: 16-inch intuitive touchscreen

- Efficient gas system: Closed-loop design minimizes consumption

- Built-in material database: Pre-validated settings for multiple materials, including precious metals

With these advantages, FUSiON S fits a wide range of industries, including:

- Automotive

- Aerospace

- Dental

- Energy

- Tooling

- Jewelry

It’s especially ideal for projects that demand precision and complexity.

A One-Stop Shop for Metal AM

ADDiTEC CEO Brian Matthews put it best:

“The launch of FUSiON S is a major milestone in our mission to deliver full-spectrum metal additive manufacturing solutions. We’re now better equipped than ever to meet the demanding needs of industries from aerospace to healthcare.”

By offering LDED, LMJ, and LPBF, ADDiTEC gives customers the flexibility to choose the right tool for the job—whether it’s prototyping, manufacturing intricate components, or conducting field repairs. This one-stop solution simplifies workflows and improves supply chain efficiency.

Final Thoughts

ADDiTEC’s FUSiON S isn’t just another 3D printer—it’s a symbol of innovation. With its expanding tech portfolio and user-friendly design, ADDiTEC is leading the way toward a faster, safer, and more sustainable future in metal 3D printing.

As the industry keeps evolving, ADDiTEC will be there—helping businesses turn bold ideas into real-world breakthroughs.