3D printing solutions for cranial implants are making real progress in personalized, just-in-time healthcare.

The EXT 220 MED has already been used in over 80 cranial implant surgeries

Doctors at University Hospital Basel have successfully performed their first facial implant surgery using a 3D-printed device made from PEEK (polyether ether ketone) material. What makes this case special is that the implant was printed directly on-site at the hospital using 3D Systems’ EXT 220 MED printer—marking a major step forward in personalized medicine that also complies with the latest Medical Device Regulation (MDR) standards.

One of the biggest reasons hospitals are embracing on-demand 3D printing is the huge time savings. It cuts down the turnaround time for producing patient-specific parts and helps streamline the medical supply chain. So far, most applications have focused on visual models for diagnosis and tools to help plan surgeries. Now, with this facial implant, we’re seeing the technology take a leap into direct clinical use.

The implant was designed and created by a team led by Professor Florian Thieringer and Dr. Neha Sharma. “Our mission is to give every patient the best possible care,” said Prof. Thieringer. “Being able to design and produce custom implants right here in the hospital means we can respond faster, tailor treatments more precisely, and improve surgical outcomes. This kind of on-demand production opens up a whole new chapter in personalized care.”

3D-Printed PEEK Facial Implants Are Now a Clinical Reality

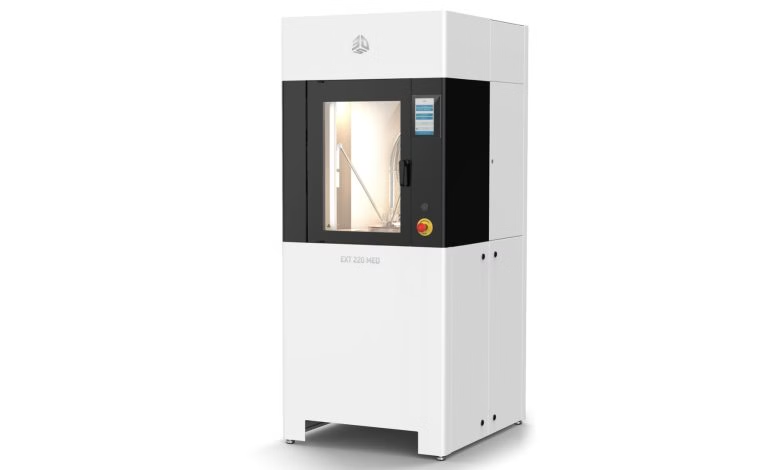

The facial implant used in this surgery was made from VESTAKEEP® i4 3DF PEEK, a high-performance, medical-grade thermoplastic produced by Evonik. Known for its excellent bone integration properties, this material was printed layer by layer using the EXT 220 MED system.

This printer is specially designed for medical environments, with a clean-room-ready build and a temperature-controlled chamber that ensures high-quality results and strong biocompatibility—both essential in healthcare.

Since acquiring German company Kumovis GmbH in 2023 (formerly the maker of Kumovis R1), 3D Systems has officially integrated the EXT 220 MED into its medical product lineup. The system has already been adopted by leading hospitals around the world and has been used in more than 80 cranial implant procedures. Now, University Hospital Basel has joined the list, completing its first on-site 3D-printed facial implant surgery—a big step forward for real-time medical manufacturing.

Dr. Stefan Leonhardt, Head of Medical Devices at 3D Systems, shared his thoughts:

“We’re seeing the EXT 220 MED roll out quickly in top hospitals around the world, which shows just how transformative 3D printing can be in clinical settings. It’s a privilege to work with forward-thinking partners like University Hospital Basel to push the boundaries of personalized healthcare. The success of this facial implant highlights our ongoing commitment to innovation and precision medicine.”

As demand for customized healthcare continues to grow, the market for 3D-printed facial implants is expanding fast. Analysts predict the global market will double by 2034, reaching over $4 billion. Thanks to its ability to handle complex structures and deliver precise fits, 3D printing is becoming a go-to solution in facial reconstruction and repair—helping patients get better outcomes and more natural-looking results.