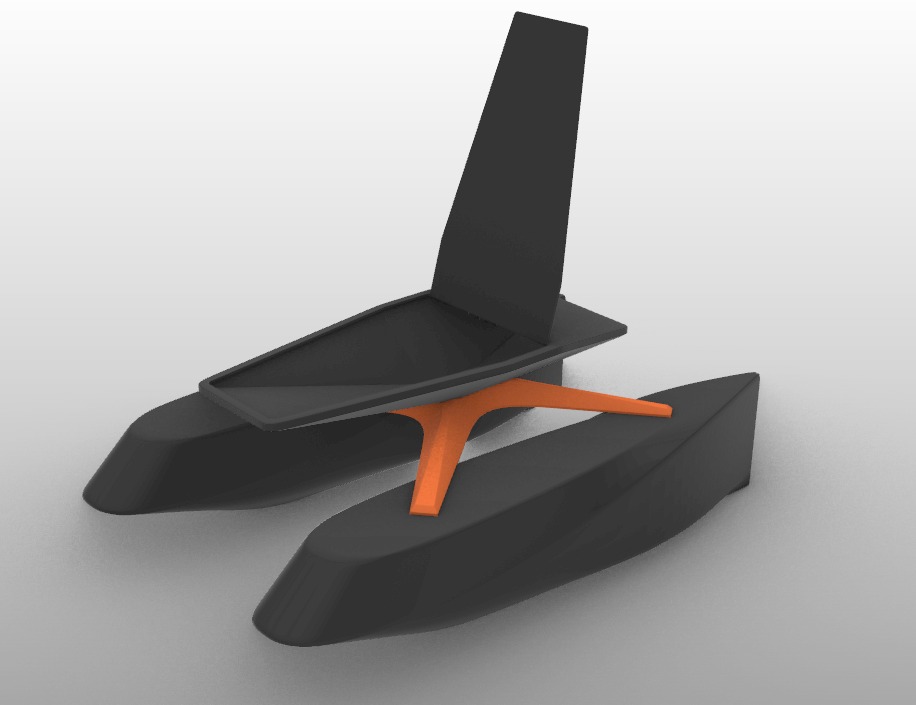

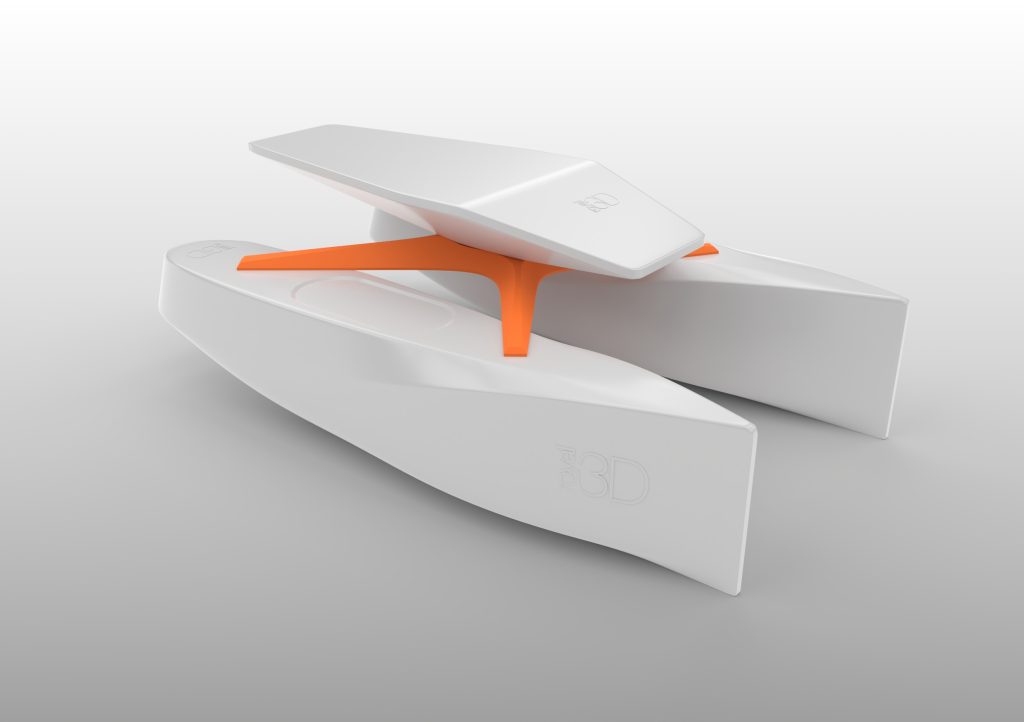

Royal3D Unveils ShearWater Aquatic Drone for Tough Maritime Jobs

Dutch 3D printing company Royal3D has just introduced the ShearWater Aquatic Drone—a brand-new prototype built to take on challenges in maritime and heavy-duty industries.

ShearWater is designed for tasks like maintenance and surveillance. It combines large-format 3D printing with strong, durable materials to perform reliably in harsh marine environments. What’s more, the drone is made entirely from recycled and recyclable materials, helping reduce environmental impact without sacrificing performance. Thanks to its modular and customizable design, companies can adapt it to their specific needs, improving both safety and productivity out at sea.

“What really makes Royal3D stand out is how we adapt cutting-edge 3D printing for sectors like maritime and heavy industry, where strength and reliability are absolutely critical,” says Fulko Roos, Founder of Royal3D and Royal Roos.

The company, based in Rotterdam, is also hosting a free event on May 24th for World Boating Day, where they’ll show live printing of the drone. Anyone interested can sign up or get in touch with Royal3D directly.

Built to Withstand the Sea

Royal3D built the drone using specially developed thermoplastic polymers and PETG fiber-reinforced materials. That gives it the strength, rigidity, and impact resistance needed for rough conditions, while still keeping it lightweight and watertight. Their proprietary 3D printing process uses infrared cameras to precisely manage how each layer sticks together, which is key to the drone’s solid build and long-term performance. This process also includes Royal3D’s own patented techniques to improve durability and reliability even more.

The ShearWater drone is part of an EU-funded Crossroads initiative, which supports tech that makes ports and marine operations safer for both people and wildlife. Through the project, Royal3D has pushed its drone technology further—making it more efficient and environmentally friendly.

With over 10 years of experience in large-scale additive manufacturing, Royal3D has built all kinds of heavy-duty parts, from transport cradles to custom structural components. The company runs two of the largest 3D printers in Europe and delivers tough, dependable parts to demanding industries.

While Royal3D still works on creative projects in urban design and architecture, their current focus is on the maritime and industrial sectors. They’re aiming to make materials more efficient and give customers more design flexibility. Right now, one of their top priorities is helping the maritime industry with reliable, customizable solutions.

3D Printed Drones Making Waves in Maritime

3D printed drones have already been proving their value in marine environments for several years now. They’ve been used in surveillance, ship inspections, and other important maritime tasks.

Back in 2017, for example, Sembcorp Marine teamed up with DNV GL, SIMTech, and NAMIC to explore drone-assisted inspections and digital twin technology. DNV deployed drones to get a close look at ship structures, giving inspectors detailed data and keeping people out of risky situations. This was all part of Singapore’s strategy to improve advanced manufacturing and engineering.

A year earlier, the British Royal Navy launched a 3D printed UAV called SULSA from the HMS Protector during an Antarctic patrol. Built by the University of Southampton using laser sintering, the drone sent back aerial images to help with navigation—and even had potential uses in communications and targeting.

All of these examples show how 3D printed drones are becoming an essential tool for the maritime world. Whether it’s inspection, maintenance, or data collection, combining drones with 3D printing is making these jobs faster, safer, and smarter.