Temporary

Crown Resin

Temporary Crown Resin(#3164)

A high precision material for casting the coping and substructure, casting the full contour crown, casting the removable partial denture frame(RPDs) and dental inlay casting.

- Natural color, color: A1, A2, A3

- Passed toxicity test, biocompatibility test

- Antibacterial, resistant to the corrosiveness of the oral environment

- Strength>55mpa

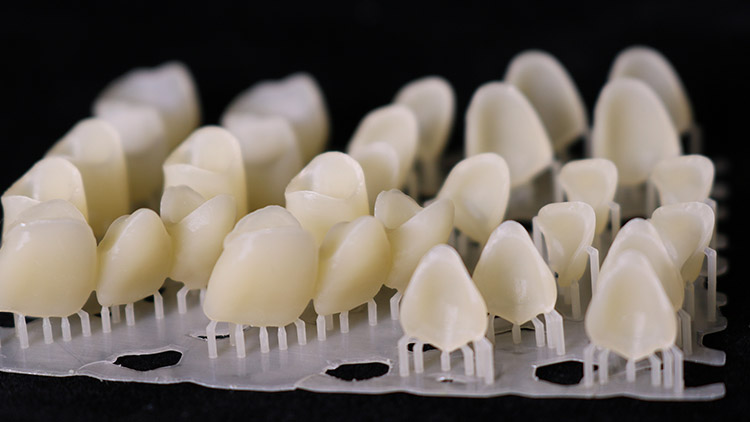

- Fast production, it only takes 50 minutes to print 88 crowns

Resin that match the color of the teeth

According to feedback from dental clinics and laboratories, the color of crowns 3D printed with 3164 resin is true to the aesthetics of the teeth; the glossy finish is good.

Fast curing, printing in 2 hours

The high quality resin material, combined with digital printing technology, makes the process of collaboration between dentist and patient more economical and faster.

Oral safety certified

3164 temporary crown resin passed the ISO 10993 biocompatibility test for cytotoxicity. Additional tests will continue to be conducted to ensure the safety of our products.

Chemical resistance

The raw materials are sourced from the United States and Japan; they have excellent mechanical properties: good elasticity, strong resistance to deformation, and strong resistance to oral corrosion, so patients can wear them with confidence.

Temporary Crown Application

How to Make and Use 3D Printed Temporary Crown Resin >>

The application process of 3D printing temporary dental crowns using resin involves the following steps:

- Scanning the patient’s teeth and gums using a 3D scanner or dental impressions.

- Designing a 3D model of the tooth using CAD/CAM software based on the scans.

- Slicing the 3D model into layers and preparing it for printing.

- Printing the model layer by layer using dental crown resin.

- Washing and curing the printed model to remove excess resin and harden it.

- Polishing the crown to give it a smooth texture.

- Applying a layer of glaze or enamel to the crown for added protection and natural appearance.

- Disinfecting the crown to ensure it is safe for use.

- Fitting the temporary dental crown onto the patient’s tooth.

- Temporarily cementing the crown onto the tooth until a permanent crown can be made and installed.

Specifications of Temporary Crown Resin(3164)

Content Data value Testing method Viscosity 350-420cps(25℃) ASTM D1084-1997 Density 1.25 ASM D1875-69(1980) Shrinkage <0.5% Capillary method Hardness85 85D ASTM D2240-05(2010) Water absorption 0.50% ASTM D570 Bending strength 55MPa ASTM D1781 Flexural modulus 1600MPa ASTM D747 Biocompatibility TEST PASS ISO10993-1/ISO10993-10

Temporary Crown Resin Print Samples

you may also need these machines

Dent Giant

This high-precision, high-efficiency dental model 3D printer guarantees batch stability

Build Size 218*128*140mm

Printing Speed 50mm/h(max)

Accuracy ±29μm

Resolution 7680*4320(8k)

Packing Weight 52kg/78kg

Packing size 400*400*580mm

Mini Giant Pro

Small size fast 3D printer for dental,Small body, big power

Build Size 143*89*150mm

Printing Speed 55mm/h(max)

Accuracy ±35μm

Resolution 4098*2560(4k)

Packing Weight 21kg

Packing size 400*400*580mm

Enable 3D Digital Production