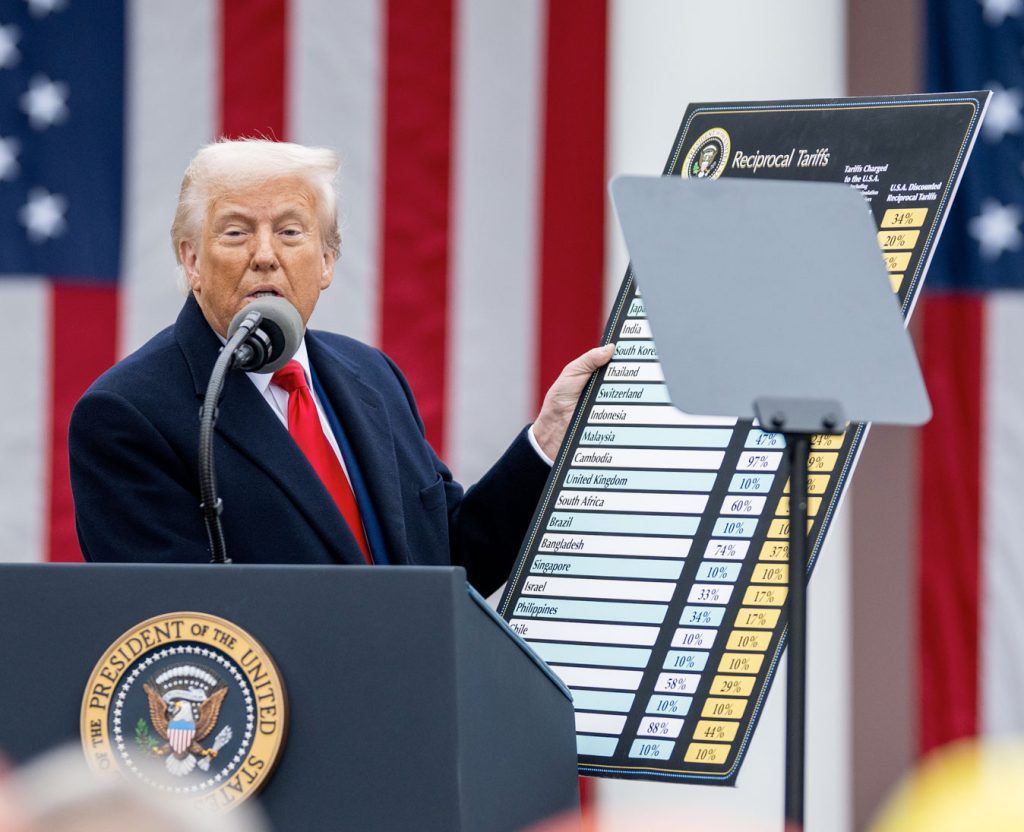

United States, April 24, 2025 – A deepening trade conflict is shaking up the U.S. 3D printing industry. New tariffs on some Chinese-made products have soared as high as 245%, and they’re driving up the cost of consumer 3D printers at a pace few expected. Hobbyists and small businesses now face a much steeper price barrier, while U.S.-made 3D printing materials are, for the moment, offering a more stable—and local—alternative.

Chinese Printers in the US: Prices Skyrocket, Availability Drops

Popular Chinese brands like Bambu Lab, Creality, Elegoo, Anycubic, and Flashforge have all seen significant price hikes in the U.S. For instance, Bambu Lab’s H2D dual-extruder printer launched at $1,899 in the U.S., but now sells for $2,699—a 23% jump. In China, the same printer costs ¥13,999 (roughly $1,900), highlighting a 40% price difference.

Their 40W laser 3D printer is another example: its U.S. price is $500 to $900 higher than expected, and it’s often out of stock. That model goes for ¥22,999 in China, again showing about a 40% gap.

“Prices have gone crazy, but people are still buying,” said one U.S. user. “I don’t get how these companies can keep operating like this. Even if they stocked up in U.S. warehouses before the tariff hit—what happens when they run out?”

Tariffs Impact: 3D Printer Prices Soar in the US

Tariffs Impact: 3D Printer Prices Soar in the US

Distributors React: Higher Costs, Fewer Imports

The concern is widespread. Tom’s Hardware recently reported that rising prices are now the norm for 3D printers in the U.S. TH3D Studio, a U.S. distributor, has stopped importing printers from China due to the 145% tariff. They’ve also had to raise prices on current inventory.

Kevin Pope, COO at MatterHackers, warned that a printer with a 25% profit margin could see its retail price rise nearly 94% just to break even after tariffs.

U.S.-Made Filament Holds Steady—for Now

While printer prices climb, domestic filament makers offer a different story. Polymaker, a major global filament supplier, won’t raise prices until May 1, thanks to stockpiles in its U.S. warehouse. Even then, the planned increase is just 10%. However, their Houston factory only serves wholesale buyers and produces limited types of filament—mainly PLA, PETG, ABS, and ASA—with a $1,000 minimum order.

Local Brands Lean Into “Made in USA” Advantage

American filament companies are now highlighting their homegrown supply chains. Polar Filament, based in Michigan, said all of its core materials—including resin, color additives, spools, and packaging—come from U.S. sources. They’re even building their own injection molding equipment to make spools in-house.

Their basic PLA sells for $18.99, and premium colors go for $21.99. They also offer free shipping for orders of three spools or more.

Printed Solid’s CEO, David Randolph, echoed the value of local sourcing. Many American filament brands rely on companies like NatureWorks, which turns Nebraska-grown corn into PLA pellets.

What’s Next? Big Challenges—and Big Opportunities

Right now, tariffs are creating major headaches for U.S. consumers and distributors. Printers are getting more expensive, and sourcing strategies are under pressure. Some companies may have to absorb costs just to stay in the game.

Still, there’s a silver lining: this could be a turning point for U.S.-based 3D printing. Companies with local supply chains now have a chance to shine—and possibly grow. For buyers, though, finding affordable, high-performance 3D printing tools just got a lot more complicated.

The U.S. 3D printing landscape is changing fast, and these new pressures could reshape the market in the months ahead.