3D printing has transformed from a niche hobby into versatile technology applied across industries, from rapid prototyping in design studios to mass production in manufacturing. A common question among enthusiasts and professionals alike is: “how much does a 3d printer cost? “, Understanding the full scope of 3d printer pricing is essential, not only to budget for the device itself but also to account for hidden and long-term costs.

The 3D printing market offers a wide range of machines that cater to everyone from beginners to large-scale production facilities. Whether you are shopping for an entry-level 3d printer or planning an investment in an industrial 3d printer, it is crucial to grasp the different factors that influence the final price. This guide delves into price ranges, technical specifications like print speed, printing precision, build volume, and even acceleration, and highlights the hidden costs you should consider. By understanding these components, you can make an informed decision that balances performance with budget.

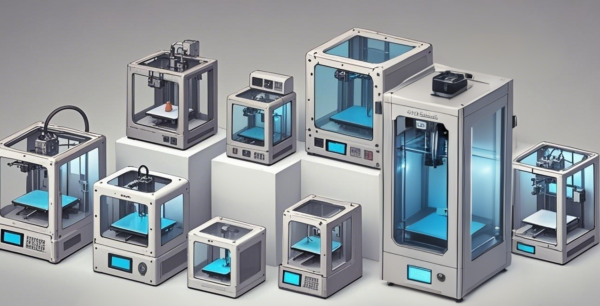

3D Printer Categories

3D printers can be broadly classified into four categories:

- Entry-Level 3D Printers:These are perfect for beginners. Generally available as DIY kits or compact machines, they offer basic functionality. Their design often prioritizes ease of use over speed or precision.

- Hobbyist/Prosumer 3D Printers:Aimed at serious enthusiasts and semi-professionals, these machines deliver improved features. They often include enhanced auto-calibration routines and better material compatibility to support a wider range of filaments such as PLA, ABS, Nylon, Carbon Fiber.

- Professional 3D Printers:Designed for small businesses, educators, and design studios, these printers offer high performance, reliable printing precision, and larger build volumes. They are built for frequent use and provide more robust customer support.

- Industrial 3D Printers:These high-end devices are engineered for mass production and complex material usage. They incorporate advanced features such as enclosed building chambers and integrated automation systems that often include AI integration in 3d printing.

Each category is tailored to different user needs, affecting both the base cost and the long-term operational cost of ownership.

Price Ranges and Market Overview

Understanding market dynamics is key to evaluating 3d printer cost. Typical price ranges include:

- Entry-Level:Approximately $100–$500 These are budget-friendly options that make 3D printing accessible, though often with limitations in speed and print size.

- Hobbyist/Prosumer:Approximately $500–$1,500 With improved components and expanded material compatibility, these printers offer better performance for detailed projects.

- Professional:Approximately $1,500–$10,000 Professional machines provide higher precision, increased build volume, and faster print speed, which are vital for regular use in a business or educational setting.

- Industrial:$10,000 and up Designed for complex tasks and continuous operation, industrial printers come with premium features such as superior acceleration and robust safety measures.

Market trends indicate that technological advances, such as automation and open-source software ecosystems, can either drive prices down by increasing competition or push them up through the integration of cutting-edge features. Low-cost models can sometimes set lower average prices, but they often come with higher maintenance cost and potential hidden costs in terms of consumable expenses.

Key Factors Influencing Cost

Several critical factors contribute to the final 3d printer cost:

Technical Specifications

- Print Speed & Printing Precision:Higher speeds and better precision come with sophisticated hardware that can significantly affect pricing.

- Build Volume & Acceleration:A larger build volume and efficient acceleration mechanisms allow for bigger and more complex prints but also drive up costs.

- Advanced Features:Innovations like auto-calibration and enclosed build chambers add to the machine’s expense, enhancing safety and reliability.

Material Compatibility & Consumable Costs

- Material Variety:The ability to print with diverse materials such as PLA, ABS, Nylon, Carbon Fiber and even metals impacts the cost. Machines that support a wide range of materials tend to be pricier.

- Consumable Expenses:Beyond the printer, users must consider the printing material cost and other consumables which can contribute to the overall operational cost.

Build Quality & Durability

- Component Quality:Higher-quality components ensure longevity and reduce the maintenance cost, although they require a higher initial investment.

- Reliability & Maintenance:Durable machines offer better ROI 3d printer results over time, especially for intensive usage.

Software & Ecosystem

- User Interface & Firmware Updates:A seamless software experience, regular firmware updates, and additional features like remote monitoring can influence the printer’s price.

- Integrated Ecosystem:The availability of an extensive support network and additional services adds value, making the investment worthwhile for professionals.

ROI and Long-Term Investment Considerations

Evaluating a 3D printer purchase is not just about the sticker price; it’s also about the return on investment (ROI) over its lifespan:

- Initial vs. Ongoing Costs:Consider both the upfront purchase price and the recurring costs for maintenance, software licensing, and material replacements.

- Usage Scenarios:Different user scenarios—from personal projects to commercial production—will have varying ROI. For example, a hobbyist 3d printer may suit personal creativity, while a professional 3d printer could lead to significant cost savings in a small business by reducing prototyping expenses.

- Operational Efficiency:Higher performance machines with better print speed and reliability can result in lower long-term costs, particularly when factoring in maintenance cost and material waste reduction.

- When assessing ROI, it is crucial to evaluate both tangible benefits and hidden expenses that might impact long-term investment outcomes.

Buying Guide and Decision-Making Factors

Choosing the right 3D printer requires careful evaluation of your specific needs and budget constraints. Here are some key decision-making factors:

- Define Your Requirements:Determine the necessary build volume, printing precision, and print speed required for your projects.

- Performance vs. Price:Evaluate the balance between high performance and affordability. A cost vs performance 3d printer can help ensure that you do not overpay for features you won’t use.

- Consider Hidden Costs:Look into potential hidden costs such as equipment maintenance, software updates, and consumable prices before making a decision.

- Market Research:Refer to a comprehensive 3d printer buying guide that outlines user reviews and expert opinions to find the best value 3d printer for your needs.

- Future-Proofing:Consider machines that support upgrades or have an active development community to keep up with future 3d printing market trends.

By weighing these factors, you can confidently choose a printer that offers the ideal balance of quality, features, and affordability, be it an affordable 3d printer for hobbyists and professionals or a high-end model for continuous industrial use.

Future Trends in 3D Printing Technology and Cost

The landscape of 3D printing is continuously evolving. Here are a few trends that are poised to influence 3d printer pricing:

- Technological Advancements:The incorporation of automation in 3d printing and AI integration in 3d printing is expected to improve printing accuracy and efficiency, potentially leading to cost reductions over time.

- Open-Source vs. Proprietary Systems:Open-source platforms may drive down prices by fostering innovation and community-driven support, while proprietary systems might maintain higher prices due to exclusive features and enhanced support.

- Sustainability Initiatives:With the growing emphasis on eco-friendly practices, the use of sustainable materials and energy-efficient designs is likely to shape future pricing models.

- Market Expansion:As the industry matures, increased competition will likely result in a wider range of price points, offering more options for both beginners and large-scale industrial applications.

These trends not only affect the initial 3d printer cost but also the long-term operational cost and maintenance cost, making it essential for buyers to stay informed about industry developments.

Choosing the right 3D printer

Choosing the right 3D printer involves understanding a broad spectrum of factors—from the basic price to technical specifications like print speed, build volume, and auto-calibration features, all the way to long-term ROI and hidden costs. By evaluating your specific needs and considering the entire cost structure, you can identify a printer that offers both exceptional performance and sustainable value.

For hobbyists and professionals alike, the key is to strike a balance between initial affordability and ongoing investment. Stay updated with the latest 3d printing market trends and emerging technologies to ensure that your choice remains relevant in a fast-evolving field. Ultimately, whether you opt for an entry-level 3d printer, a professional 3d printer, or even an industrial 3d printer, making an informed decision will pave the way for creative success and long-term profitability.