T800 Castable Wax Resin Bracelet Printing & Casting Case

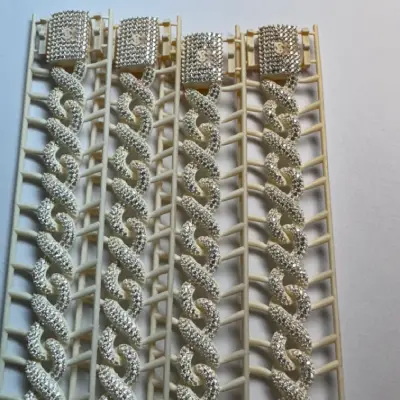

Model Geometry & Detail Retention: Whether it’s the minute circular tennis chain links, the complex twisted Cuban chain, or honeycomb pave setting holes, T800 ensures high resolution and sharp edges in the printed model. Complex herringbone structures remain securely on the supports, proving the material’s stiffness for printing thin walls.

Reliability of Pre-setting: All setting holes on the resin model possess highly consistent geometric dimensions, laying the groundwork for efficient, high-volume gemstone pre-setting. T800 allows for stable fixation of multi-color and different-sized gemstones on the model, withstanding the pressure of the pre-setting operation.

Excellent Lost-Wax Casting Results (Casting Success Rate): The finished casting proves that the T800 resin achieved a complete, clean burnout, ensuring no residue remains in the mold cavity. The metal casting perfectly replicates all subtle textures and geometric structures of the resin model. The casting surface quality is high, minimizing post-casting finishing and polishing workload.

Benefits of Cast-in-Place (Pre-set Casting): The metal casting clearly shows the pre-set gemstones being effectively and securely wrapped and fixed by the metal prongs. This technique is suitable for complex curved pave settings, making it an ideal choice for the mass production of challenging setting styles.

For more details and case studies, please feel free to inquire!