Austin, TX — July 1, 2025 — Researchers at The University of Texas at Austin have unveiled a groundbreaking 3D printing method that can seamlessly merge rigid and flexible materials within a single object. Inspired by nature’s ability to integrate strength and flexibility—like the tough bone encased in soft cartilage—this new technique may revolutionize fields such as prosthetics, flexible electronics, and wearable medical devices.

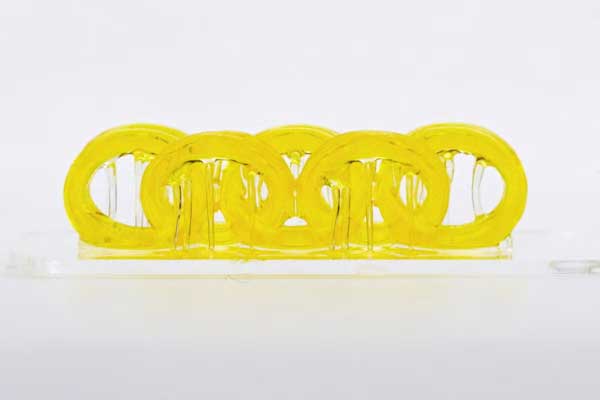

Published in Nature Materials, the study introduces a novel dual-wavelength photopolymerization process. It relies on a custom-engineered liquid resin and two different light sources to initiate distinct chemical reactions. When exposed to violet light, the resin cures into a rubber-like, flexible material; under high-energy ultraviolet light, the same resin solidifies into a rigid, plastic-like substance.

“We wanted to replicate the way nature organically fuses soft and hard materials without mechanical failure at the interface,” said Dr. Zak Page, assistant professor of chemistry and lead author of the study. “By engineering a molecule that responds to both wavelengths of light, we enabled two curing reactions to communicate and create a much stronger bond between regions.”

One of the major hurdles in multi-material 3D printing has been the weak interface between different material types. Traditional manufacturing often sees layers delaminate—such as rubber soles peeling off running shoes. The UT Austin team addressed this by designing molecules that contain dual-reactive groups, ensuring seamless transitions between soft and hard zones.

In a related paper published in ACS Central Science, Page’s team demonstrated the technology by printing:

- A functional knee joint model with flexible ligaments and rigid bones that move in harmony,

- And a stretchable electronic prototype with embedded gold wiring—featuring both bendable and stiff sections to protect the circuitry.

The technique boasts higher resolution, faster curing speeds, and simpler hardware compared to existing multi-material systems. This makes it an accessible solution for engineers, designers, educators, hospitals, and research labs alike.

“This could truly redefine how we approach additive manufacturing,” said Keldy Mason, co-author and graduate student in Page’s lab. “By using light not just to cure resin, but to sculpt material properties on demand, we’re giving creators more freedom and expanding the design space.”

Potential applications include:

- Custom-fitted prosthetics with embedded flexibility,

- Surgical training models that mimic human anatomy,

- And soft robotics with both pliable and structural parts.

“This is just the beginning,” added Page. “We’re excited to see how this technology empowers new solutions across medicine, electronics, and beyond.”