Resin-printed temporary crown offer numerous advantages, but they also present certain challenges. This article examines both the inherent limitations of these crowns and the potential failures caused by 3D printing or resin material issues. Additionally, it delves into the underlying causes of these problems and provides practical solutions.

Advantages of Resin 3D-Printed Temporary Dental Crowns

Resin 3D-printed temporary dental crowns offer the following six major advantages:

High Precision and Excellent Fit

- 3D printing technology (especially DLP/SLA) achieves precision within ±50 microns, ensuring a close match between the crown and the natural tooth, reducing the need for adjustments.

- Digital scanning + CAD design avoids errors from traditional manual fabrication, improving marginal fit and enhancing comfort and functionality.

Rapid Production, Improved Clinical Efficiency

- Traditional temporary crown fabrication (hand-carved or cast) may take several hours to a day, while 3D printing can complete a crown in just 20-30 minutes, significantly reducing patient wait times.

- Suitable for immediate restoration, especially for providing temporary crowns quickly after dental implants or tooth preparation, enhancing patient experience.

Customizable Design for Personalized Needs

Using CAD/CAM software, dentists can precisely design crown morphology, occlusion, and anatomical structure based on the patient’s oral condition, improving aesthetics and comfort.

Adjustable color, thickness, and morphology meet diverse patient needs, particularly in aesthetic areas like anterior teeth.

Biocompatibility and Durability

- Biocompatible resin materials (e.g., Bis-GMA, UDMA composite resins) are FDA, CE, and ISO 10993 certified, ensuring safety without irritating gums or causing allergic reactions.

- Excellent mechanical properties:

- High compressive strength (withstands normal chewing forces), reducing cracking risk.

- Wear resistance (moderate surface hardness, less prone to premature wear).

- Hydrolysis resistance (resists deformation or degradation in the oral environment).

Lower Economic Costs

- Reduced material waste: 3D printing uses precisely calculated resin amounts, minimizing waste compared to CNC milling.

- Lower labor costs: Eliminates extensive manual fabrication or adjustments, relying on digital workflows, suitable for bulk production in dental clinics and labs.

- Bulk production capability: A DLP/LCD printer can produce multiple crowns in one batch, significantly reducing per-unit costs.

Versatile Clinical Applications

- Temporary implant crowns: Provide aesthetic restoration during osseointegration while avoiding excessive implant stress.

- Post-tooth preparation restoration: Protects prepared teeth, preventing sensitivity and damage.

- Occlusal adjustments: Digital designs can refine occlusion for improved comfort.

- Long-term temporary use: Some high-performance resins are suitable for medium-term wear (3-6 months), ideal for complex cases.

With high precision, rapid production, customization, excellent biocompatibility, and cost-effectiveness, resin 3D-printed temporary crowns are becoming a vital choice in modern dental restoration. As resin materials and 3D printing technology continue to advance, their applications will expand further, enhancing patient experience and clinic efficiency.

Limitations of Resin 3D-Printed Temporary Crown

Common Issues with Resin 3D-Printed Temporary Crown

Despite their advantages, resin 3D-printed temporary crowns may encounter the following problems:

- Limited Durability

- Resin materials are weaker than metals or ceramics, making them prone to wear or fracture under chewing pressure.

- Prolonged use may cause marginal wear, compromising seal integrity.

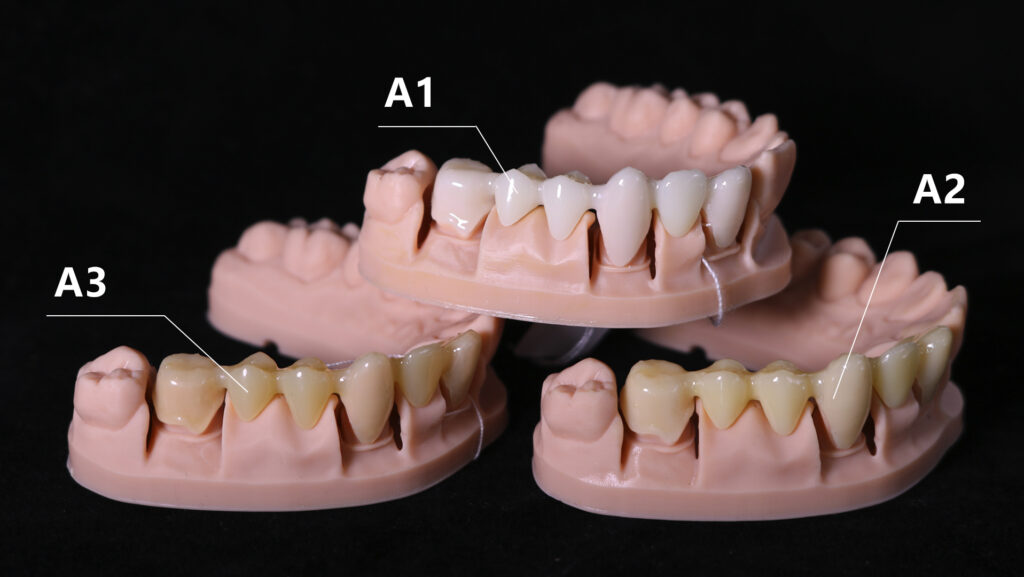

- Color Stability

- Resin may discolor over time, especially when exposed to pigmented beverages like coffee, tea, or red wine.

- Long-term use can lead to yellowing or darkening, affecting aesthetics.

- Water Absorption and Oral Environment Impact

- Resin absorbs water, potentially causing slight dimensional changes that affect fit.

- Prolonged use may promote bacterial growth, increasing risks of oral odor or inflammation.

- Bonding Stability

- Temporary crowns often use temporary dental cement, which may loosen or detach over time.

- Hard foods can exacerbate loosening or detachment.

- Mechanical Performance and Fracture Risk

- Excessive force may cause micro-cracks or fractures, especially in posterior teeth or patients with strong bite forces.

- Compared to metals or ceramics, resin has lower compressive strength and may deform under prolonged stress.

Root Cause Analysis of Common Issues

Issue | Possible Causes |

Limited Durability | – Resin’s lower mechanical strength makes it prone to wear/fracture. – Chewing pressure over time may damage margins, compromising seal. |

Color Stability | – Resin absorbs pigments from food/drinks (e.g., coffee, tea). – UV/chemical exposure may cause discoloration or yellowing. |

Water Absorption & Oral Impact | – Water absorption causes slight expansion, affecting fit. – Moisture promotes bacterial growth, leading to odor/inflammation. |

Bonding Stability | – Temporary cements are weaker, prone to loosening over time. – Hard foods generate shear forces, increasing detachment risk. |

Mechanical/Fracture Risk | – Lower compressive strength, especially in posterior teeth. – Layer-by-layer printing may create weak points, increasing fracture risk. |

How to Address Temporary Crown Issues?

- Avoid hard foods to reduce excessive pressure.

- Use high-performance resins (e.g., nano-filled composites) for better wear/fracture resistance.

- Limit pigmented foods/drinks to minimize discoloration; opt for UV-stable materials.

- Maintain oral hygiene to prevent bacterial buildup.

- Replace with permanent crowns promptly to ensure long-term oral health.

By optimizing resin materials and usage, 3D-printed temporary crowns can balance short-term functionality while mitigating common issues. Follow dentist guidance for timely permanent crown placement.

Issues Caused by 3D Printing or Resin Failures

When 3D printing or resin use fails, the following problems may occur:

Structural Issues (Morphology, Fit)

Issue | Possible Causes |

Dimensional Errors, Poor Fit | – Inaccurate 3D scan data causing model errors. – Unaccounted resin shrinkage or inadequate adaptation gaps. – Printer misalignment leading to dimensional deviations. |

Poor Marginal Seal, Gaps | – Improper support settings during printing, causing warping. – Incomplete post-curing, resulting in unstable material properties. |

Occlusal Issues | – CAD design inaccuracies in simulating patient occlusion. – Insufficient printing resolution, compromising detail precision. |

Mechanical Performance Issues (Durability, Strength)

| Issue | Possible Causes |

|---|---|

| Crown Fracture or Chipping | – Layered printing structure reduces interlayer strength. – Resin lacks sufficient flexural/impact resistance. |

| Warping or Deformation | – Poor temperature control during printing, causing stress. – Uneven curing leads to non-uniform material shrinkage. |

Biocompatibility and Oral Adaptation

Issue | Possible Causes |

Gum Irritation/Inflammation | – Incomplete curing leaves residual solvents/monomers. – Materials fail biocompatibility standards (e.g., ISO 10993). |

Water Absorption/Swelling | – Low-quality resins absorb water, causing expansion. – Oral moisture accelerates material degradation. |

Poor Taste/Odor | – Subpar resins trap food/bacteria, causing odor. – Inadequate post-processing (cleaning/curing) leaves residues. |

Aesthetic Issues

| Issue | Possible Causes |

| Color Mismatch | – Unstable resin hues fail to match natural teeth. – Uneven curing causes localized discoloration. |

| Long-Term Discoloration | – Resin absorbs pigments from food/drinks. – UV exposure yellows or fades photosensitive materials. |

How to Avoid 3D Printing or Resin Failures? Optimization Strategies for Temporary Crown Printing

To minimize failures in 3D-printed temporary crowns, optimize each stage—scanning, design, printing, post-processing, and clinical application—as follows:

Scanning & Data Acquisition: Ensure Accurate Input

- Issue: Incomplete or low-precision scans lead to poor fit or dimensional errors.

- Solutions:

- Use high-precision intraoral scanners (e.g., 3Shape TRIOS, Medit i700).

- Scan in a dry environment; apply powder if needed to improve accuracy.

- Regularly calibrate scanners to prevent drift.

Crown Design & CAD Modeling: Optimize Morphology and Fit

- Issue: Poor CAD designs affect occlusion, fit, or support structures.

- Solutions:

- Set 100-200 μm gap between crown and tooth for stability and easy bonding.

- Simulate occlusion using software (e.g., Exocad, 3Shape CAD).

- Apply 1-2% expansion compensation to account for resin shrinkage.

- Optimize support structures to prevent warping while preserving surface quality.

3D Printing: Precision Process Control

- Issue: Low precision, warping, or weak interlayer adhesion.

- Solutions:

- Choose the right technology:

- DLP/LCD: Fast, ideal for bulk production.

- SLA: High precision for quality crowns.

- Use high-resolution printers (≤50 μm layer thickness).

- Print at a 10-15° tilt angle to reduce supports and improve strength.

- Optimize exposure time, layer thickness, and light intensity.

- Choose the right technology:

Post-Processing: Enhance Mechanical & Biocompatible Properties

- Issue: Incomplete curing, low strength, or biocompatibility problems.

- Solutions:

- Clean thoroughly: Use >95% IPA (ultrasonic clean for 3-5 minutes, twice).

- Post-cure optimally:

- UV cure for 5-10 minutes (material-dependent).

- Cure in nitrogen/oxygen-free environments to prevent stickiness.

- Polish gently: Use soft rubber wheels + diamond paste to smooth surfaces.

Clinical Application: Improve Comfort and Durability

- Issue: Loosening, fractures, or gum irritation.

- Solutions:

- Select appropriate cement:

- Short-term (<2 weeks): Zinc oxide-based (e.g., TempBond).

- Long-term (>2 weeks): Resin-modified (e.g., Premier Implant Cement).

- Advise patients to avoid hard foods.

- Monitor stability and replace crowns if issues arise.

- Select appropriate cement:

Stage | Optimization Strategy |

Scanning & Data | Use high-precision scanners; avoid humidity interference. |

CAD Design | Set proper gaps, simulate occlusion, compensate for shrinkage. |

3D Printing | Select suitable technology, adjust print angle, optimize parameters. |

Post-Processing | Clean thoroughly, post-cure properly, polish surfaces. |

Clinical Use | Choose appropriate cement, avoid hard foods, monitor stability. |

By optimizing these five stages, 3D-printed temporary crowns can achieve higher precision, durability, and patient comfort while reducing failure rates.