Exploring the Future of Jewelry Manufacturing: The Charisma of Wax 3D Printers

Introduction:

With the continuous evolution of 3D printing technology, an increasing number of industries are leveraging this innovation for creativity and production. In the field of jewelry manufacturing, wax 3D printers are gaining prominence, becoming the preferred choice for many jewelry designers and manufacturers. This article delves into the advantages of wax 3D printers and how they are redefining the traditional jewelry manufacturing process.

1. Introduction to Wax 3D Printers:

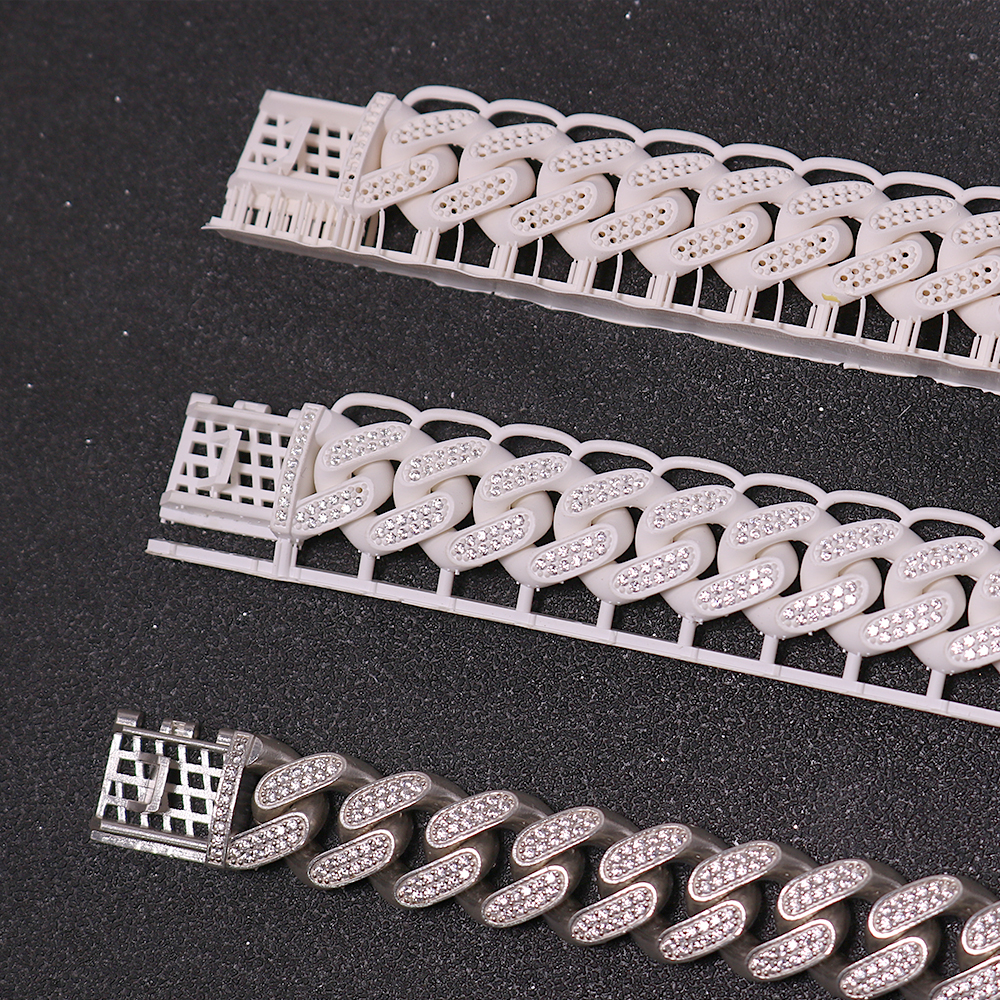

Wax 3D printers are specially designed 3D printers for the jewelry industry, using high-performance wax resin as their raw material. The high precision and delicacy of wax resin allow the printer to produce jewelry models with exquisite details and textures.

2. Advantage One: Perfect Blend of High Precision and Complexity:

Wax 3D printers achieve remarkably high printing precision by layering white wax resin. This precision empowers jewelry designers to create designs that were previously unimaginable in terms of intricate and complex details, enhancing the overall artistic appeal.

3. Advantage Two: Rapid Prototyping:

The traditional jewelry manufacturing process may take weeks to complete a new design prototype. In contrast, a wax 3D printer can accomplish a complex jewelry prototype in a matter of hours, providing designers with a more flexible creative space. This also means manufacturers can swiftly bring new designs to market, responding promptly to market demands.

4. Advantage Three: Customized Production:

Wax 3D printers are not only used for mass production but also excel in customized production. Through digital design, customers can order uniquely tailored jewelry designs based on personal preferences, enhancing consumer engagement and satisfaction.

5. Future Outlook:

As technology continues to innovate, wax 3D printers will play an even more significant role in jewelry manufacturing. In the future, we can anticipate the application of advanced materials and the emergence of faster, more precise printing technologies, unlocking further possibilities for the jewelry industry.

Conclusion:

The rising prominence of wax 3D printers marks the arrival of a new era in digital jewelry manufacturing. Whether it’s improving production efficiency, enabling customized designs, or driving overall industry innovation, this technology has brought about a revolutionary change in the jewelry manufacturing landscape. Looking ahead, as technology evolves, we can expect more captivating moments where 3D printing redefines traditions in the jewelry industry.